First published August 2015

Find out what heat pumps are and how they work. Plus the five different types of heat pump system, their benefits and disadvantages.

Quick links:

- What is a heat pump?

- How does a heat pump work?

- The five types of heat pump system

- The pros and cons of each type of heat pump system

What is a heat pump?

Heat pumps take low grade heat from the ground, water or air and boost it to higher temperatures to make it useable for heating. Boosting temperatures through the heat pump uses conventional refrigeration/air conditioning technology and as such requires the input of electrical energy.

Heat pumps have a number of advantages over other heat sources:

- Minimal maintenance

- No bulky fuel deliveries necessary

- Less plant room space required

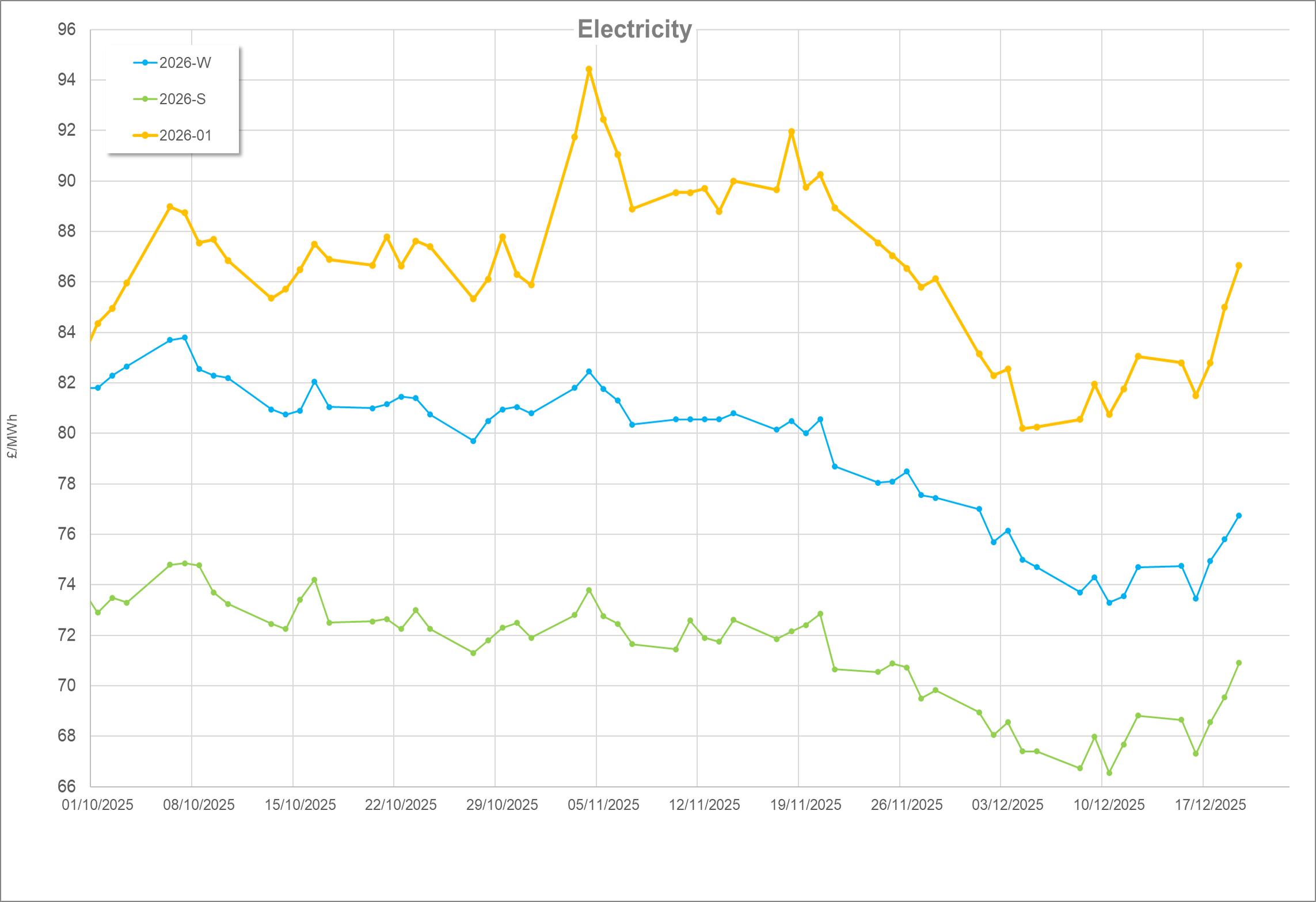

Heat pump efficiency

The efficiency of heat pumps is defined by their Coefficient of Performance (CoP). A heat pump will require less electrical power than the quantity of heat it can deliver. The CoP is given as a ratio which should be greater than one and most likely in the region of 2.5 – 5, i.e. between 2.5 kW and 5 kW of heat delivered for each 1 kW of input power. Similarly this ratio can be expressed in average terms over time and is often given as a Seasonal Performance Factor or SPF. An SPF of 3 means 3 kWh of used. The RHI requires that the SPF for an accredited system is greater than 2.5 and its CoP betters 2.9.

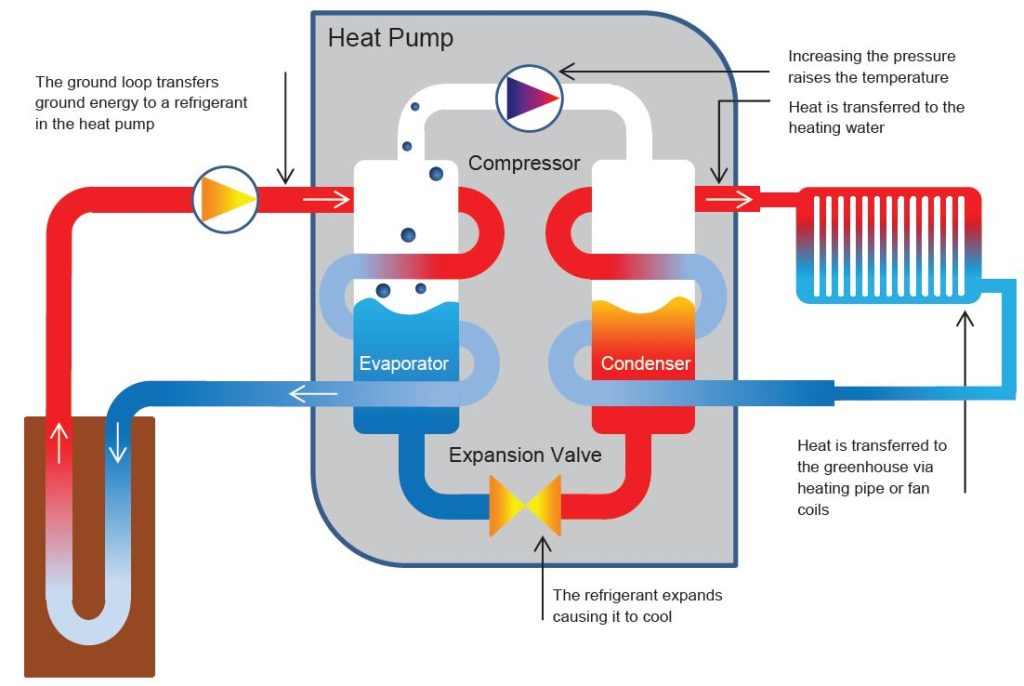

How does a heat pump work?

The general principles of how a heat pump works, irrespective of type.

The heat energy contained in the ground or water loop is taken up by a refrigerant in the evaporator. The gas in the evaporator is warmed up. The gas is then compressed which further increases its temperature and pressure. The gas is cooled in the condenser and becomes liquid, useful heat is obtained for space or water heating here. Following this the high pressure liquid refrigerant passes through an expansion valve which rapidly decreases its pressure causing the liquid to evaporate and become very cold. This allows the refrigerant to take up more heat for the cycle to continue.

The five types of heat pump system

An explanation of each of the five types of heat pump system, how each works and the factors to consider when choosing a system to install.

There are five types of heat pump system which differ according to the heat source.

Vertical Closed Loop Boreholes

This approach is very effective and requires minimal land. Boreholes (usually around 150mm in diameter) are drilled vertically, typically up to 150 metres deep. Collector pipes filled with glycol liquid are inserted as a “closed loop” into the borehole which is backfilled with a thermal grout. The loops are connected via flow and return to a manifold chamber and the heat pump.

Drilling boreholes can be costly, so this type of heat pump installation is used when there is no water source available or the amount of land available is insufficient or unsuitable.

Open Loop Boreholes

Open loop boreholes can be utilised when there is a reliable, consistent subterranean supply of ground water. Establishing the suitability of a water supply accurately requires the drilling of a test borehole, but an initial desktop study can be undertaken by a Hydrogeologist, usually at low cost.

In an open loop system, water taken from a borehole provides the heat. The water can then be used for other purposes or returned to the ground in a second borehole that is some distance from the first. Abstracting water for use in an open loop heat pump requires consent and a licence from the Environment Agency. Water is being returned to the ground after use. Obtaining approvals and licences can be time consuming, sometimes taking up to 12 months although non-consumptive licences tend to be easier and quicker.

Temporary licences may be obtained while the application is being progressed. However, obtaining a temporary licence is no guarantee of full approval and drilling costs will be significant, so proceeding without approval is risky.

Desk surveys are not a guarantee that water will be available in sufficient quantity. A desk survey will provide a strong indication of the available water supply and your consultant Hydrogeologist should advise you of any potential issues as well as the degree of certainty associated with your land. It is advisable to make a test drilling to measure the actual water flow before committing to the full heat pump installation.

Nurseries or holdings with an existing borehole for irrigation water can consider using them as a heat source, thereby saving additional drilling costs albeit the amount of heat may be limited unless the water quantity is sufficiently large or more water can be made available.

Horizontal Loop Ground Source

This approach is more cost effective than a vertical loop system. A horizontal loop system can be a good solution when sufficient land is available. Trenches are excavated to a depth of 1.2 m and collector pipes laid. As an approximate guide, for every acre of glasshouse requiring a frost free environment (heating to 6˚C) approximately one acre of land will be needed for the collectors.

Water Source Closed Loop Heat Pump – lake/river

Reservoirs, lakes or even rivers can be used as closed loop water sources and, if these are available are cost effective solutions. The collectors are placed in the water in stacked coils and tied down. The collectors will function even when the surface water has frozen.

The labour costs associated with this are less than both the ground source options and there is less disturbance during the installation.

Air Source (ASHP)

As the name suggests air source heat pumps use neither ground or water as the heat source but the ambient air around them. However the technology is identical after the heat has been collected. The RHI rate for ASHP is considerably less than for ground source and water source heat pumps and while they could be a practical alternative to fossil fuel heating for packing sheds, offices and other relatively small spaces, the size and low return on investment for an ASHP of sufficient capacity for heating greenhouses will be prohibitive.

The pros and cons of each type of heat pump system

A comparison of the five types of heat pump system, their benefits and disadvantages.

| Pros | Cons | |

| Vertical Closed Loop Boreholes | Reliable. Borehole sized to meet system requirements. No planning, EA approval or licenses required. High efficiency (though less than water source) Minimal maintenance Can also provide cooling as the chilled water returning to the boreholes can be intercepted and used, which also replenishes the boreholes so that fewer are required | Drilling can be expensive, typically £35 per metre Higher capital cost Most horticultural applications will require many vertical boreholes. At 150m deep, 13 boreholes in 550m2 would be needed to yeild 100 kW. approx, costing around £70k. |

| Open Loop Boreholes | Cheaper than closed loop boreholes Very efficient Water temperature is stable year round Minimal disruption to site | Drilling can be expensive, typically £35 per metre Water extraction licenses required Filtration set required, specified by the environment agency and potentially expensive Test borehole required with no guarantee of performance or grant of license |

| Horizontal Ground Loop Source | Reliable Groundworks likely to be considerably cheaper than a vertical closed loop system for equivalent heat throughput | Requires a relatively large land footprint. Typically 1000m2 to provide 12°C temperature lift for each 1000m2 glasshouse. Potential damage to buried collectors by agricultural machinery unless sufficiently deep Restriction of future groundworks on the land |

| Water Source Closed Loop Heat Pump (lake/river) | Cheaper than closed loop boreholes No license required for lakes High efficiency Very reliable Little maintenance | Lake or body of water needed nearby Lake required to be large and at least 1.5m deep Waterway approval may be needed for rivers Boats/debris could damage pipework |

| Air Source (AHSP) | Lowest capital cost Reliable Can be used for heating and cooling | Available capacities generally insufficient for heating greenhouses Can sometimes be noisy Considerably lower RHI tarriff |