First published 2016

How to find areas where air is leaking, including the use of thermal imaging, and the potential cost of unnecessary air leakage.

Back to: Cold store efficiency: What we can learn from Denmark

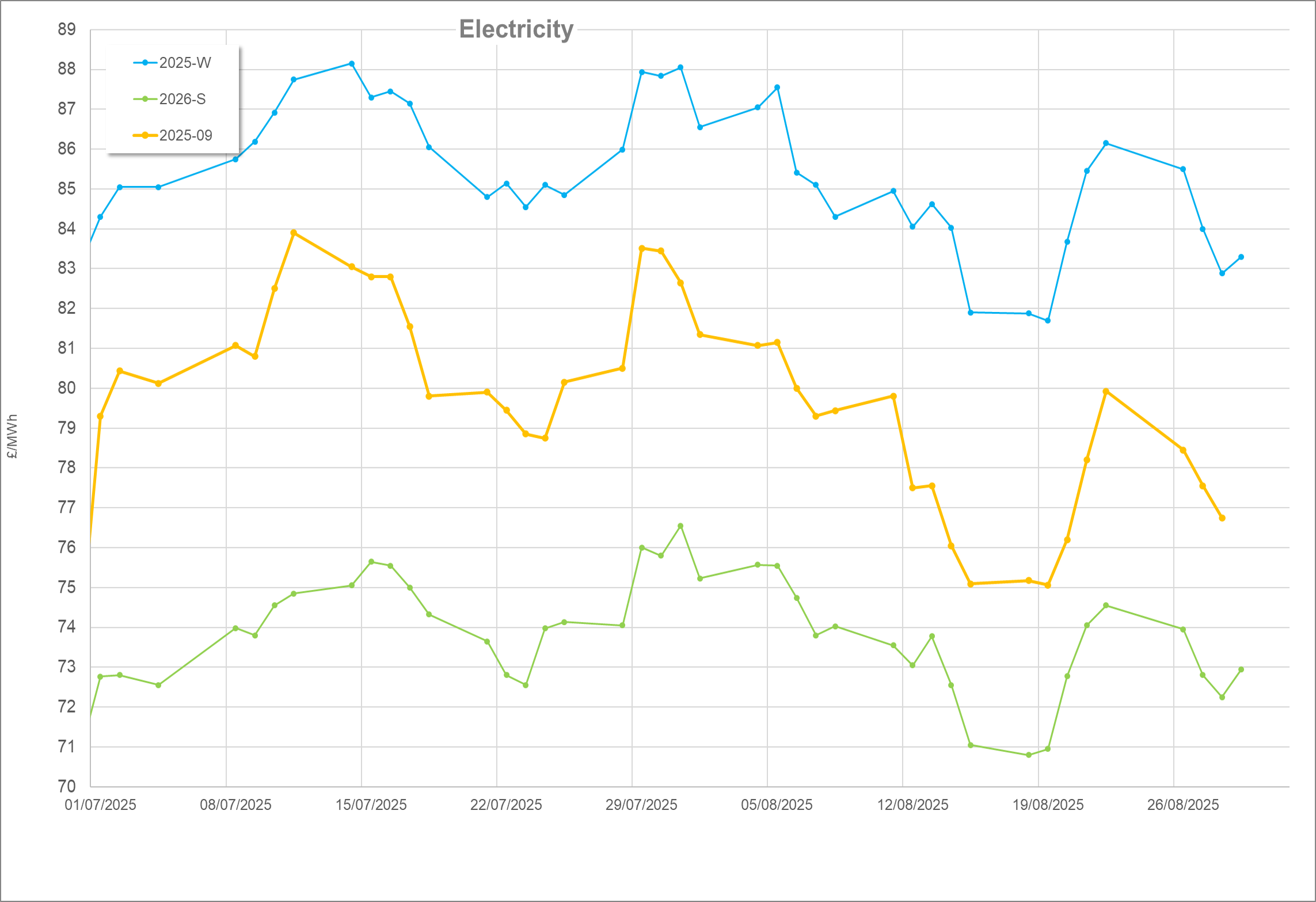

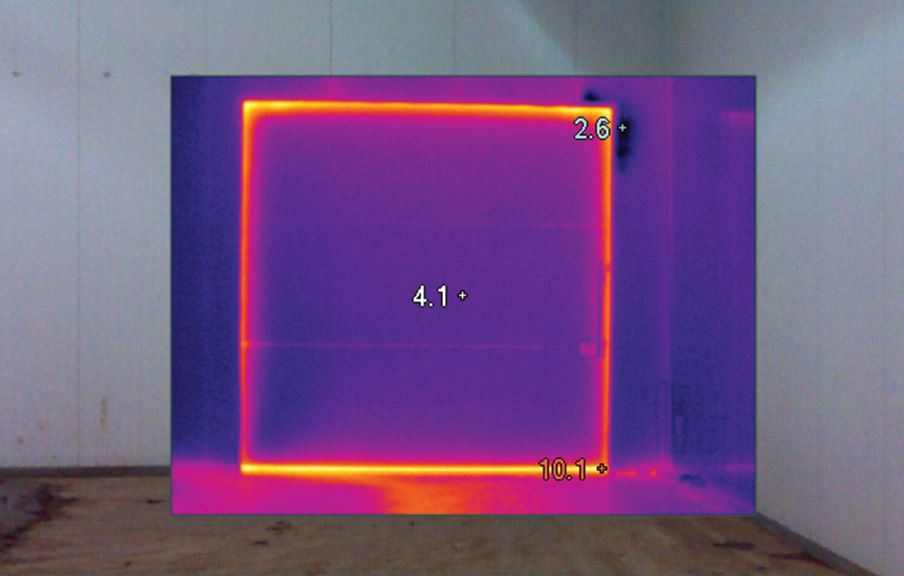

Uncontrolled air exchange will contribute to increasing electricity costs for cold storage. Areas where air is leaking can be found by using a thermal camera, smoke testing or even by placing the back of your hand around suspect areas and feeling the air movement.

Particular areas of attention are around main and personnel doors, louvres, where refrigeration equipment enters through the store wall, and between composite panels.

Recent air leakage tests carried out in conjunction with AHDB Potatoes have shown that stores can exceed the building regulations’ target air leakage rates for cold storage and, in some cases, even exceed the targets for general commercial buildings. Unnecessary air leakage can contribute up to 50% of store running cost during periods when crop is being held at a set temperature (i.e. after initial cooling has happened).

Any store where produce is continually being taken in and out should be fitted with fast acting doors or, at the very least, strip curtains.

Thermal imaging can also be useful in determining whether insulation is effective and to look for problem areas. Particular attention should be paid to roof and wall joins and between panels, as these can often be missed when general purpose buildings are converted to stores. Minimum recommended U-values for cold stores are between 0.45 and 0.20 W/m2/°C equivalent to 50 to 120mm of PIR composite panel.