The uptake of renewable electricity production in the UK controlled environment horticulture (CEH) industry has been lower than other sectors. In large part, this is because CEH set-ups in glasshouses do not have the large open spaces or unused roof areas needed for the popular generation options. Agrivoltaics has potential to change this dynamic.

Simply, agrivoltaics is defined as the dual use of land for both crop/livestock production and photovoltaic (PV) electricity generation. In CEH, this comes in the form of integrated PV panels into the glasshouse structure or polytunnel. Strictly, floating PV on reservoirs does not meet this definition of agrivoltaics, but these systems are often considered as part of the same discussion, as they make use of available space for PV generation on a working crop production site.

PV (photovoltaic) generation

The most important factor to consider with any renewable generation project is the proportion of self-use. Although export-only systems can work, greater value is available from offsetting grid import.

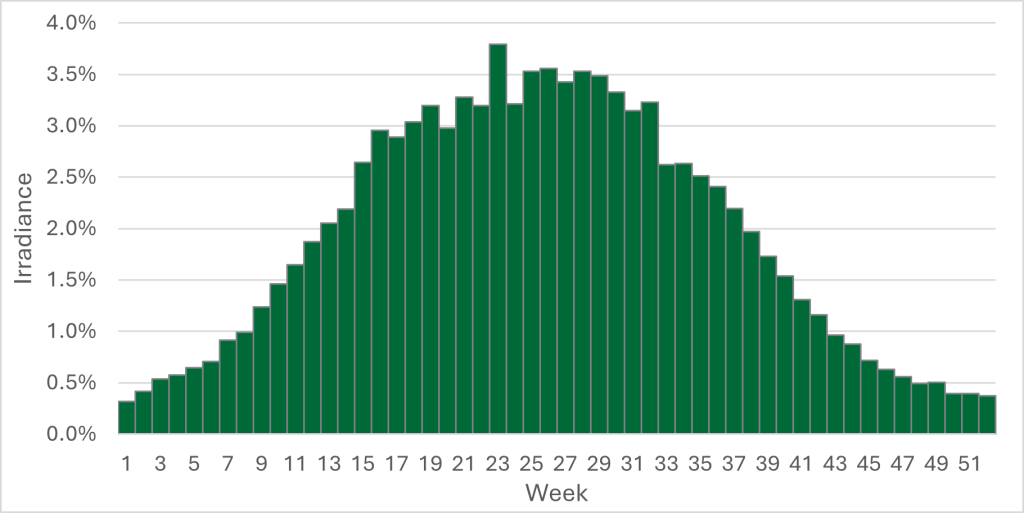

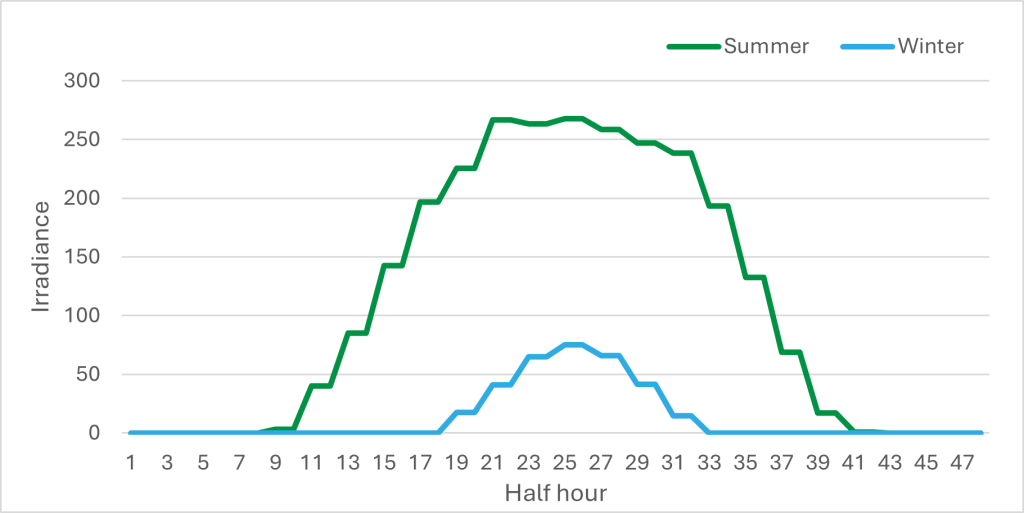

Although obvious, it is worth stating that solar PV generation follows irradiance. The figures below show total weekly irradiance data through a typical year, and the difference between typical summer and winter daytime profiles.

By knowing that PV generation will follow these profiles, its appropriateness to different processes and need profiles can be assessed. Although grow lighting tends to cause peaks in electricity consumption when used, their most common use case is either when ambient light is insufficient for the crop, or overnight for night-break lighting. Given where the peaks of irradiance lie through the day, these are clearly not good fits for PV.

Likewise, heat distribution pumps and other heat generation parasitic loads occur primarily in winter, where solar PV will struggle.

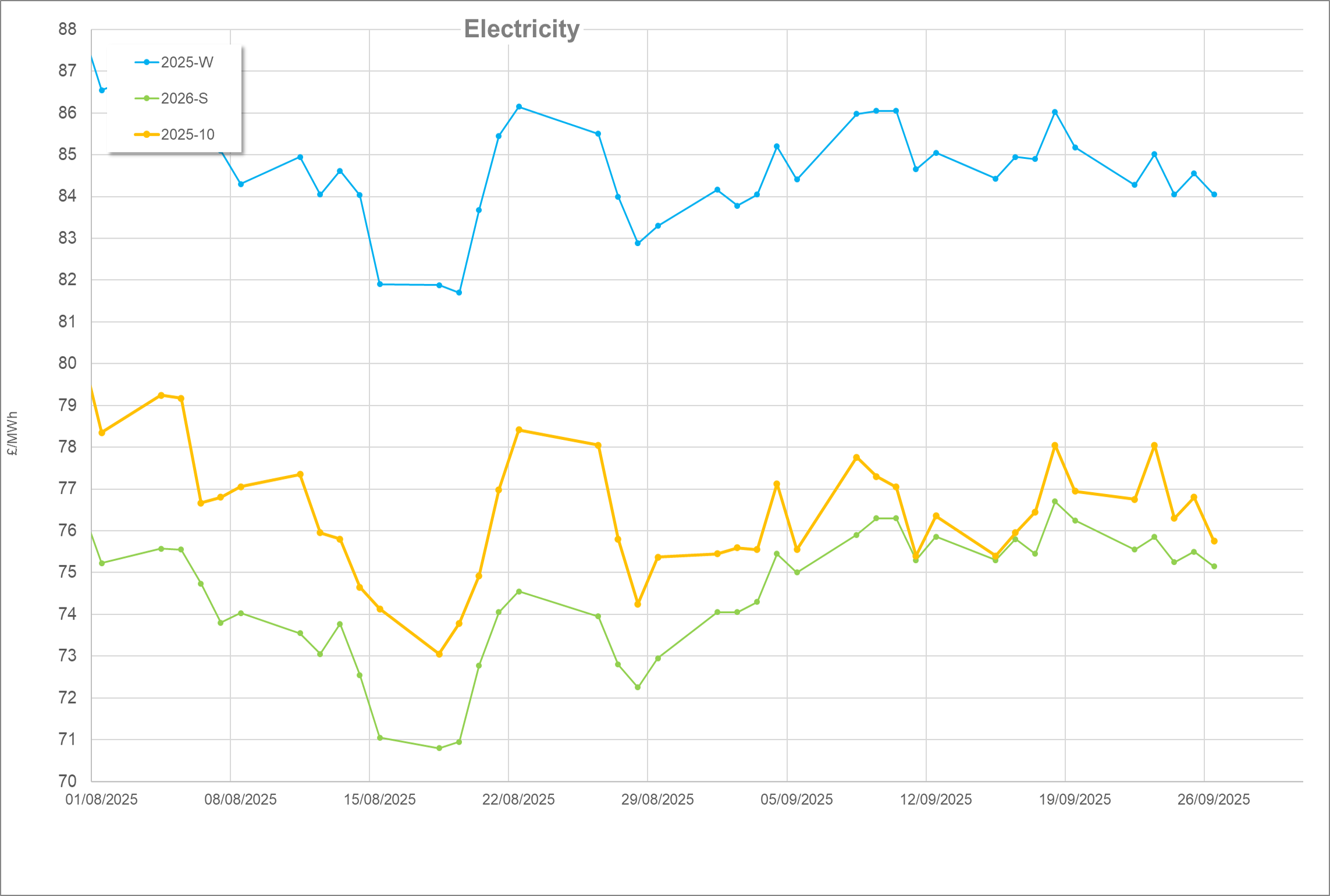

PV systems can be sized to meet these demands, but in those cases the system will be vastly oversized in summer, exporting much of its generation at a time of year when electricity is cheap.

Inter-day storage is possible (although costly) using batteries, however inter-seasonal electricity storage is not currently viable.

The remaining typical electricity loads in CEH are irrigation, air movement fans, and cold storage. In principle, these loads coincide much better with PV generation. Although used throughout the year, each of these will peak during summer daytime.

There is potential for synergy between PV generation and electrified heating, e.g. heat pumps. Clearly, peak winter heating will not benefit, but off season heating can align with PV. A negative relationship does exist: if irradiance is high, PV generation will be high, but heating requirement will likely be low. This can be overcome somewhat by using appropriately sized thermal storage.

It is worth noting that crop cooling is becoming a greater consideration in UK CEH, which lines up perfectly with PV generation. Additionally, some agrivoltaic configurations can provide shading to the growing space, which helps to reduce the cooling load.

Sizing considerations

When sizing any type of PV system, appropriate data should be captured and analysed to ensure the system is not oversized and ‘wasting’ excess power by selling it to the grid.

This consideration becomes less important as the size of the system increases, as economies of scale and the available electricity markets mean that the system can still achieve a reasonable payback period by selling power to the grid.

However, it is possible that this oversizing strategy will become less viable in the near future. Each year, more and more solar PV is installed in the UK, becoming a larger proportion of our grid mix. The issue is that the grid will eventually start to reach saturation point, the beginnings of which can already be seen with electricity spot-price becoming negative during periods of high wind generation.

The effect will be mitigated somewhat by improvements in storage and the electrification of heating and transport sectors; but this only pushes the saturation point further, rather than solving the problem.

Agrivoltaics options for protected cropping

Floating solar

The simplest and most common way to integrate PV with horticulture is floating PV covering reservoirs. Fundamentally, the panels are no different from regular ground-mounted systems, but they are mounted to a floating platform which is anchored into the reservoir.

Floating PV benefits from making use of otherwise empty space, without any compromise in terms of ordinary glasshouse operation. In fact, anecdotally, operators of floating PV installations note that reservoir evaporation is lower, which benefits water availability and reduces pumping costs.

Although relatively new, the technology is mature, and many installations exist across the UK. Costs tend to be slightly higher than regular ground-mounted systems, but this is not always the case, as expensive ground works are not required. Read more about this type of installation in our Floating Solar article. See some examples of different floating solar modules and set ups below:

Replacing glass with PV panels

The next most ready technology is integration with or replacement of glass with PV panels. Regular or N-type panels are particularly viable for covering walkways, chilled storage, water treatment, or office areas within the glasshouse structure. Panels exist which can be direct replacements for horticultural glass, fitting into the existing structure without modifications. Again, this allows for high-efficiency power generation without compromising on business operations.

Depending on the crop type, height of the structure, and whether diffuse screening/material is used, using integrated panels over a portion of the growing area can also be viable.

PV panels consist of a positive ‘P’ layer, and negative ‘N’ layer, the latter of which donates electrons to produce current, and the former acts to recapture the electrons from the other side of the circuit. Most PV panels are P-type, meaning the P layer is the majority of the material within the panel. Recent research has shown that N-type panels (which have mainly N material), have much better efficiencies and resistance to degradation.

Semi-transparent PV

Less ready is transparent/semi-transparent PV. The general rule is that as panels become more transparent, their efficiencies decrease. This makes sense, as PV panels use the energy in sunlight to produce power. If the sunlight is passing through, the energy is not being converted.

A pear orchard in Bierbeek installed semi-transparent PV panels (allowing a minimum of 75% Photosynthetically Active Radiation) above a portion of their trees [1]. Initial results showed that electricity production was around 40% that of a similarly sized traditional PV system, and crop yields were just over 16% lower. This is promising, especially as they mention other potential benefits such as high-sun shading, hail protection, and spring heat retention.

A more extreme example is Royal Pride in Middenmeer, who commissioned a 15ha greenhouse whose roof is entirely comprised of semi-transparent PV panels [2], totalling 31.2MW of generation capacity. The structure is open, and they have not yet decided what crops to grow underneath (although tomato and cucumber are clearly off the table), instead waiting to get real transmission data before committing to a crop. The benefit here is that the structure is generating value even when empty.

Spectral selective PV

Finally, the least ready, but potentially most exciting, application is ‘tuneable transmission’ or ‘spectral-selective’ PV. These use novel materials such as quantum-dot or perovskites which can dynamically adjust the wavelength and intensity of light which they transmit.

Potentially, the technology could get to a point where adjustments could be made based on key ambient and growing metrics (temperature, humidity, etc.) to provide scorch shading, reduce solar gains, and remove non-photosynthetically active wavelengths of light to both improve growing conditions and generate power.

What are the perceived challenges and opportunities for adoption of agrivoltaics? We will share more information on this soon…

This article was written by Eirinn Rusbridge

[1] https://iiw.kuleuven.be/apps/agrivoltaics/bierbeek.html

[2] https://www.hortidaily.com/article/9573469/solar-panel-greenhouse-being-realized-in-netherlands/