Introduction

Glass has been used as a greenhouse covering material for centuries, and for good reason. Light transmission, chemical stability, resistance to ultraviolet (UV) degradation, structural integrity, and ease of cleaning are all properties that make it very well suited to the task. However, fragility and heat transmission remain poor. Considering the cost of heating greenhouses, the movement towards a more closed environment, and how modern alternative materials have progressed, the application of those materials warrants further discussion.

Alternative Materials

Although many materials are available and have been used at various points in time, the following materials will be explored here, chosen for how commonly they are used and how beneficial their properties are:

- Polyethylene (PE),

- Polycarbonate (PC),

- Ethylene Tetrafluoroethylene (ETFE).

A key concept to understand with all covering materials is the trade-off between light transmission and thermal resistance. Whereas weight may be a limiting factor for implementing double-glazed glass for thermal resistance (alongside cost and condensation risk), plastics are much lighter. This means that thicker materials, or multiple layers with air gaps, are much more common with non-glass materials.

When these are used, the limiting factor becomes light transmission, which decreases as the thickness or number of layers increases. The resulting decrease in photosynthesis, or increased cost for supplemental lighting, will need to be balanced against the cost savings from reduced crop heating and a more stable temperature environment.

Although visible light transmission is a useful comparator, the sun delivers radiation across a much broader spectrum. Additionally, photosynthetically active radiation (PAR) is not the only useful radiation that outdoor crops receive. UV light can also be important for some crops in producing colour, flavour, and morphological characteristics. Additionally, some pollinators may suffer in the absence of UV light. Traditional glass has almost no UV-B transmission but does transmit UV-A.

As with glass, plastic materials can be tailored to their application. For example, manufactured with diffuse properties, restricted/unrestricted UV transmission, selective wavelength transmission, anti-drip properties, and so on. Typically, plastic materials with these properties are cheaper than specialised glass, although this is not always the case.

Additionally, since all plastic alternatives are lightweight and versatile, this can allow for wider truss spacing and therefore less structural shading within the greenhouse.

Polyethylene

PE is by far the most common plastic used in controlled environment horticulture, being the material used for polytunnel coverings. Often it comes as a roll of film, but multi-layer arrangements are also available.

The primary benefit of PE is its low cost, as much as ten times lower than glass. Single-sheet PE light transmission and thermal insulation are generally similar, if slightly worse, than glass and the expected lifespan is lower up to around five years. However, it is flexible, resistant to weather damage, and repairing small tears is cheap and easy.

PE is inherently susceptible to UV degradation, meaning that without UV stabilisation additives, its lifespan can be as low as one year. Additionally, it does not have the same infrared absorption that glass has, which contributes to the greenhouse effect. To counter this, additives are often used to prevent heat from radiating from the crop directly to the night sky. Typically, PE allows some UV-A to transmit but blocks UV-B.

Polycarbonate

The most common form of PC in horticulture is single or multi-walled corrugated panels. Its advantages are primarily in impact resistance, strength, and thermal performance. Its lifespan is typically longer than PE, up to around 10-15 years. PC ranges from a similar cost to glass, up to as much as three times the cost, depending on the design.

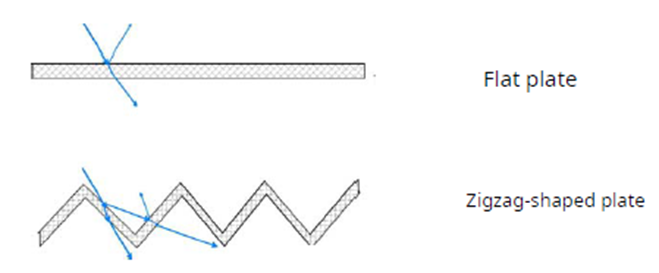

Although standard PC panels have relatively poor direct light transmission, designs with a zigzag corrugation improve diffuse transmission by capturing some of the reflected light that would otherwise be lost:

As with PE, PC is sensitive to UV exposure, so panels tend to be manufactured with high UV reflectance to prevent degradation or discolouration. The difference between them is that PC panels do not transmit UV radiation at all.

It is also important to note that PC panels are used throughout many non-horticultural sectors, and so a lot of commercially available PC panels are not manufactured for greenhouse covering. Although some of these panels might have high general light transmission, they may restrict certain beneficial wavelengths of light and restrict plant growth.

ETFE

Similarly to PE, ETFE can be installed either as a single-layer film, or a multi-layer inflated cushion. Whilst being very lightweight, ETFE has high light transmission, good durability, and a long lifespan of up to and exceeding 20 years. Cost is comparable to glass, slightly higher depending on the design. ETFE can transmit the full spectrum of UV radiation if needed.

Although not as common as other materials in the UK, ETFE is more common in other parts of the world. Its most high-profile use in the UK is in the Eden Project domes, which house a variety of plants kept at different temperature/humidity profiles. Additionally, ETFE is ‘self-cleaning’, requiring much less maintenance than other coverings throughout its long life.

Scientific Comparison

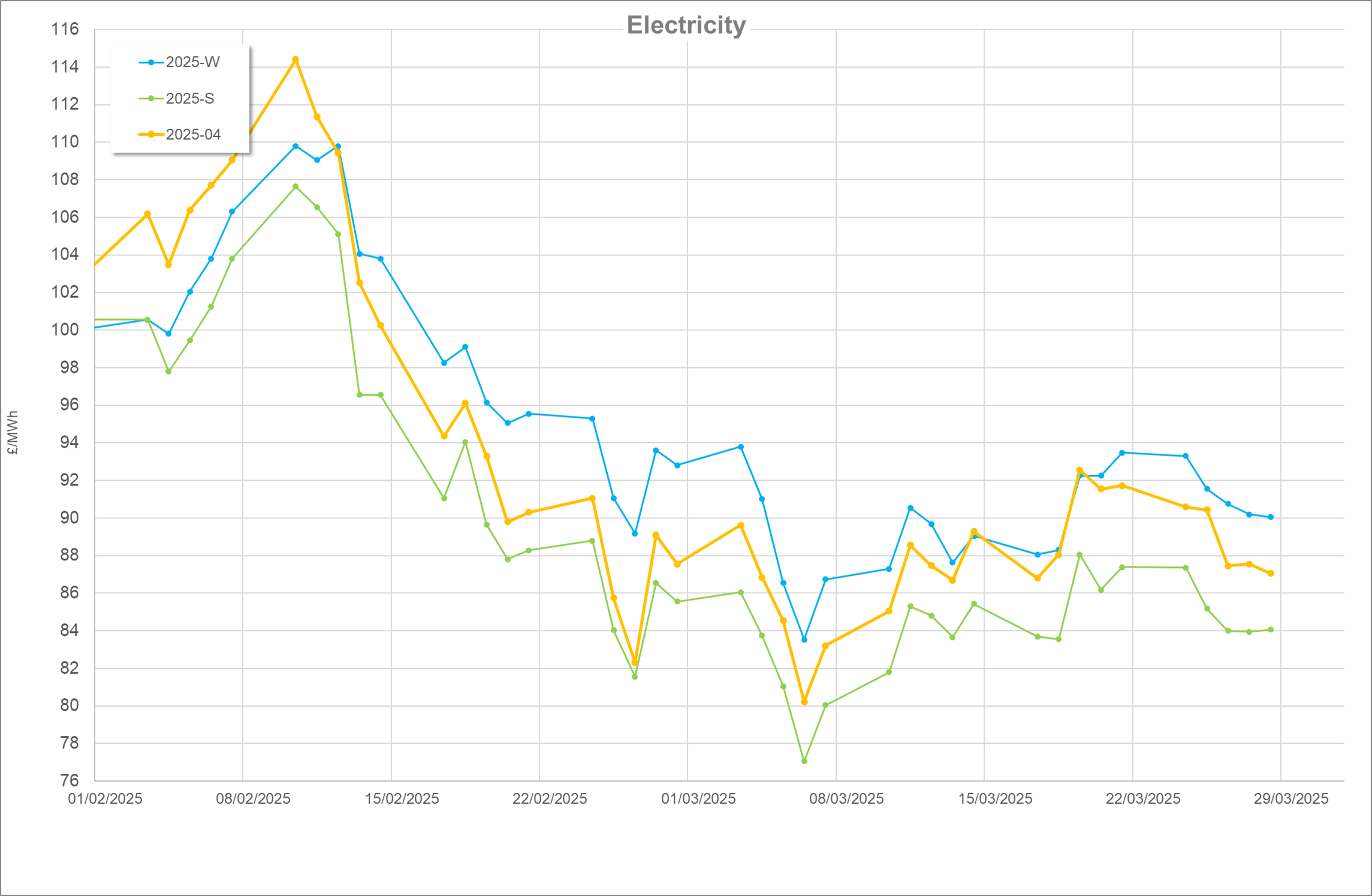

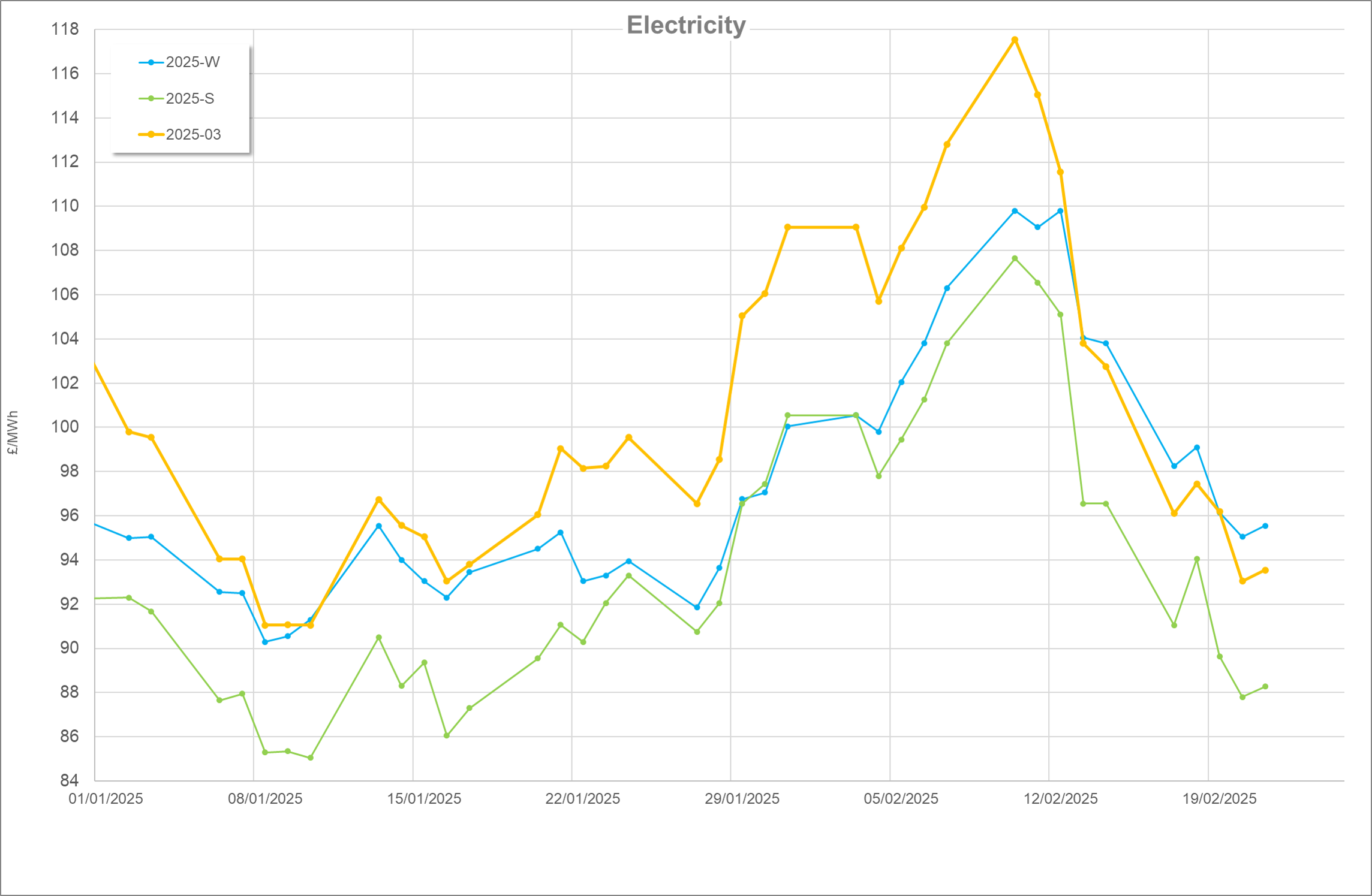

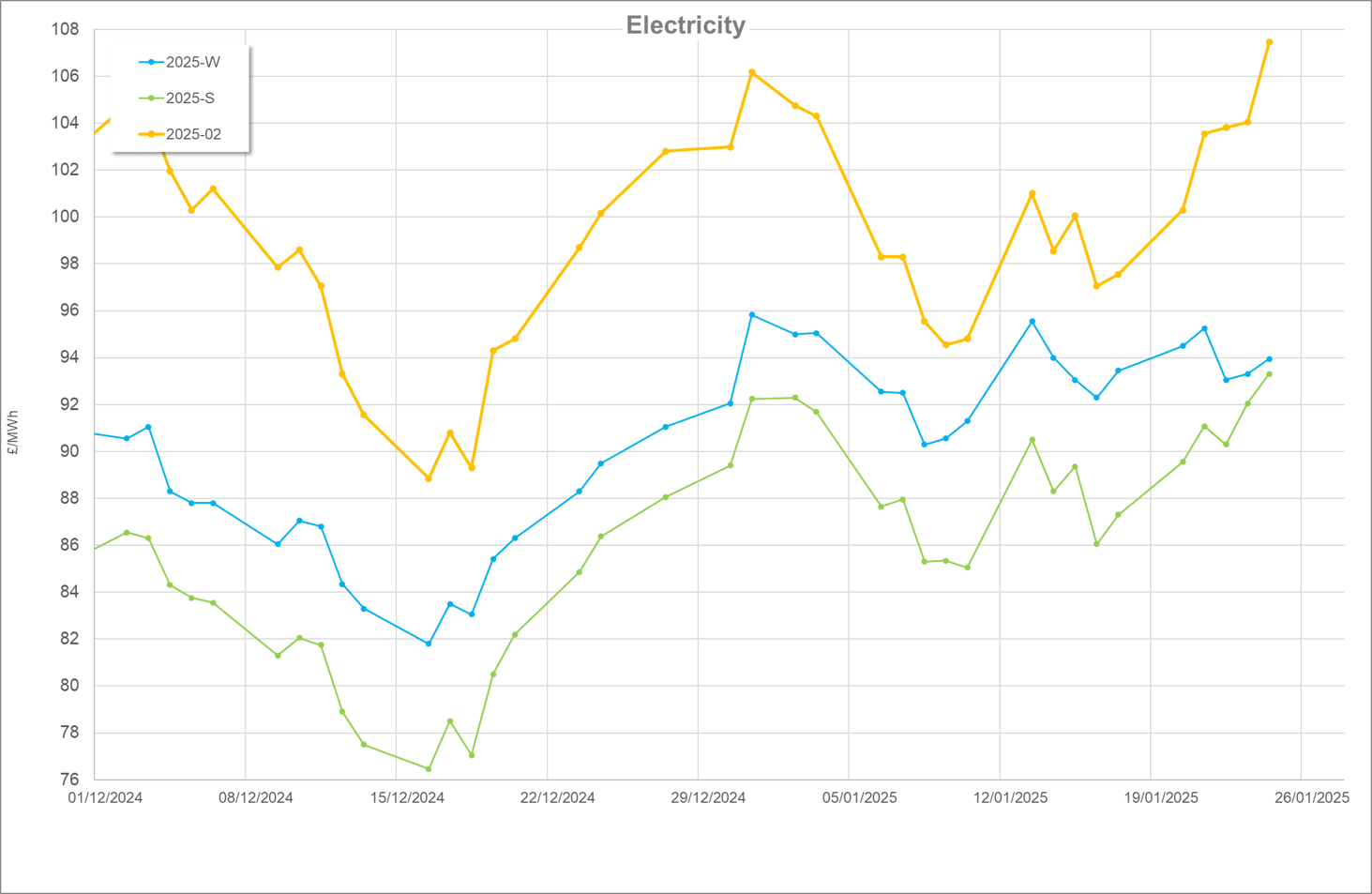

A research paper published in late 2021 [2] assessed many common greenhouse covering materials for their key performance metrics. Similar data sets are available in an older 2004 Wageningen paper [1]:

- Light transmission & reflectivity (visible spectrum),

- Solar radiation & reflectivity (whole spectrum),

- Solar heat gain coefficient,

- Heat transmission coefficient (U-value).

Clearly, the results do not represent all arrangements of these materials and the products from individual manufacturers will vary. Particularly, those that benefit from specialised characteristics such as diffuse light.

Incoming global radiation must pass through the covering material before it reaches the crop. The most important optical properties are the transmission, reflection, and absorption; shown as percentages which always sum to 100%. Whilst transmission and reflection are most applicable to visible and shorter wavelengths, absorption (and the following emission) is more applicable to the longer infrared (IR) wavelengths associated with radiative heat.

The figures outlined and discussed here are intended to give general characteristics, rather than definitive prescriptions.

| Material | Thickness (mm) | Transmission (%) | Reflectivity (%) | Solar Heat Gain Coefficient (%) | U-Value (W/m2K) | ||

| Visible | Solar | Visible | Solar | ||||

| Glass | 3.900 | 89.5 | 82.5 | 7.5 | 7.1 | 86 | 5.62 |

| PE | 0.090 | 88.4 | 89.6 | 8.2 | 7.9 | 90 | 5.88 |

| PC | 5.900 | 49.6 | 51.3 | 23.7 | 22.2 | 54 | 3.70 |

| ETFE | 0.097 | 92.3 | 92.5 | 6.6 | 6.7 | 93 | 6.03 |

Some interesting results are apparent from this data. PC is the largest outlier here, having both the lowest light transmission and u-value of these materials1. This is partially because the PC sample used was double walled, whilst both PE and ETFE were single layers. However, even single-wall PC typically has a lower light transmission and u-value. Compared to glass, PC transmitted 45% less visible light and 38% less solar radiation, offset by 34% lower heat transmission. PC panels (along with multi-layered coverings in general) can be beneficial when covering crops that prefer shade or for use as side panels where light transmission is less important.

PE performed very similarly to glass, with 1% lower visible light transmission but 9% higher solar radiation transmission, with 5% higher U-value.

The material with the highest light transmission and lowest light reflection rates was ETFE. Compared to glass, ETFE transmitted 3% more visible light, but importantly, transmitted 12% more full-spectrum radiation. This is offset by a 7% higher U-value, meaning it will more readily lose heat compared to glass. This highlights a compelling use case for ETFE, particularly covering crops that benefit from a higher DIF (difference between day and night temperatures).

F-Clean, a product range of ETFE films for horticulture manufactured by AGC, states that their double-layer films have a U-value as low as 3.8W/m2K, comparable to the multi-walled PC tested in the 2021 study. They do not specify a light transmission rate alongside this U-value, although they claim it is still high.

Whilst visiting Wageningen Research Centre as part of the 2024 Growsave study tour, it was mentioned that a strawberry crop they were growing under ETFE benefitted from cooler overnight temperatures and undesirable daytime heat loss was minimised by utilising thermal shade screens.

Conclusions

Each of these plastics, as well as glass, have their place in greenhouse construction. The most important consideration when deciding on a covering material is what the crop needs, for example:

- If shading is beneficial throughout the cropping cycle, multi-layered plastics are an attractive solution.

- When side screens (or bubble wrap) are in place for prolonged periods, multi-layered plastic panels can be used to replace side glass, to further reduce heat loss through the sides/ends.

- If maximising light transmission is the priority, then single-layer PE or ETFE paired with a wide truss structure may be worthwhile.

Regardless of covering material, appropriate screening should also be in place to minimise unwanted light/heat transmission.

References

[1] Optimal use of natural light in greenhouse horticulture – Silke Hemming et al, Agrotechnology & Food Innovations B.V. Member of Wageningen UR, 2004.

[2] Simulation Analysis of Daylight Characteristics and Cooling Load Based on Performance Test of Covering Materials Used in Smart Farms – Doo-Yong Park et al, 2021.

This article was written by Eirinn Rusbridge.

- Lower U-value means less heat loss, i.e., better thermal insulation. ↩︎