Introduction – why do we use CHP?

Combined Heat and Power (CHP) is common in UK horticulture, and with good reason; each of the outputs of heat, electricity, and CO2 are useful. Having an electricity generation asset provides a lot of resilience and versatility in how a site can provide heat, light, and CO2 to their crop, and can mitigate the impact of volatile wholesale energy prices.

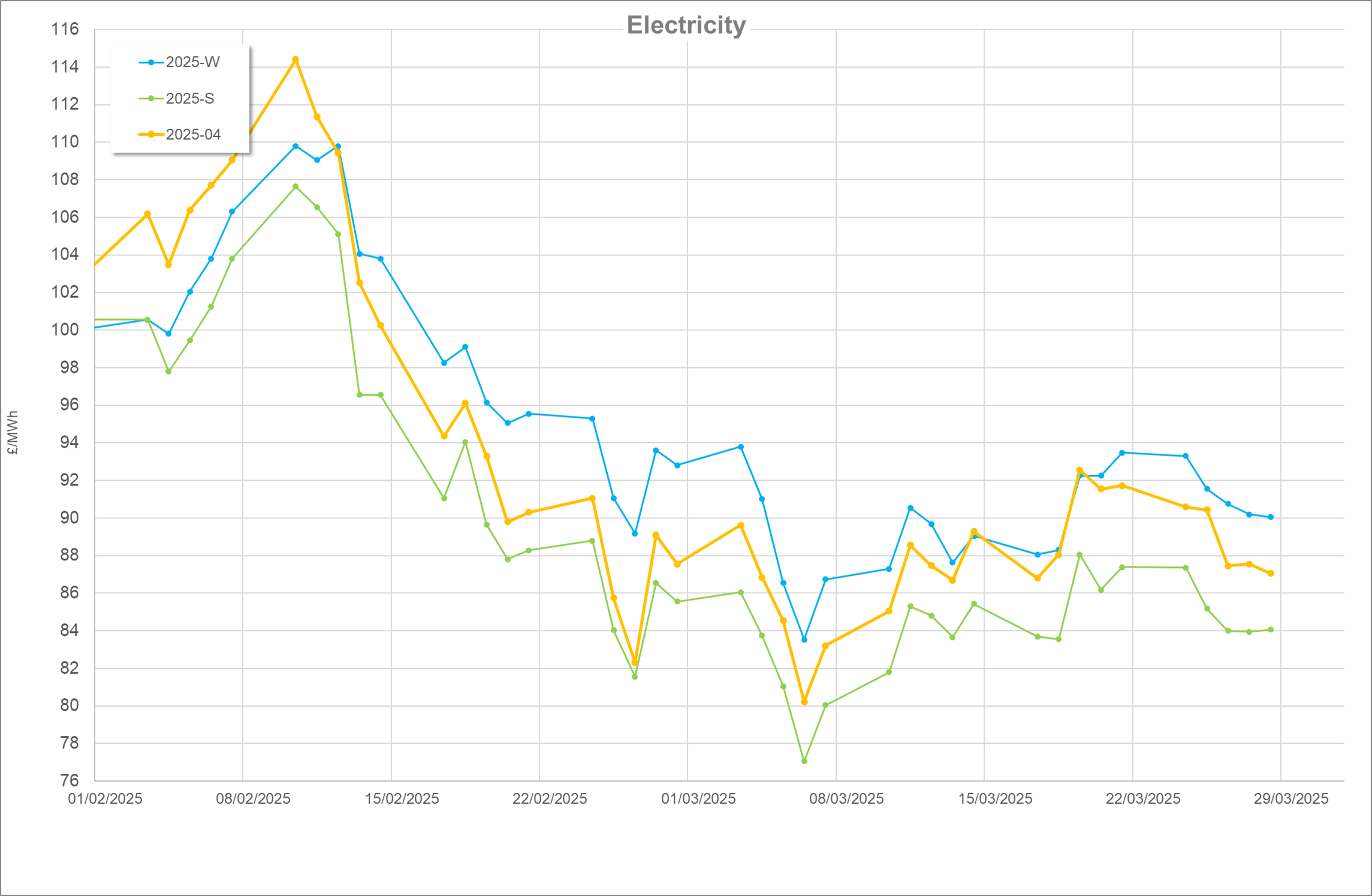

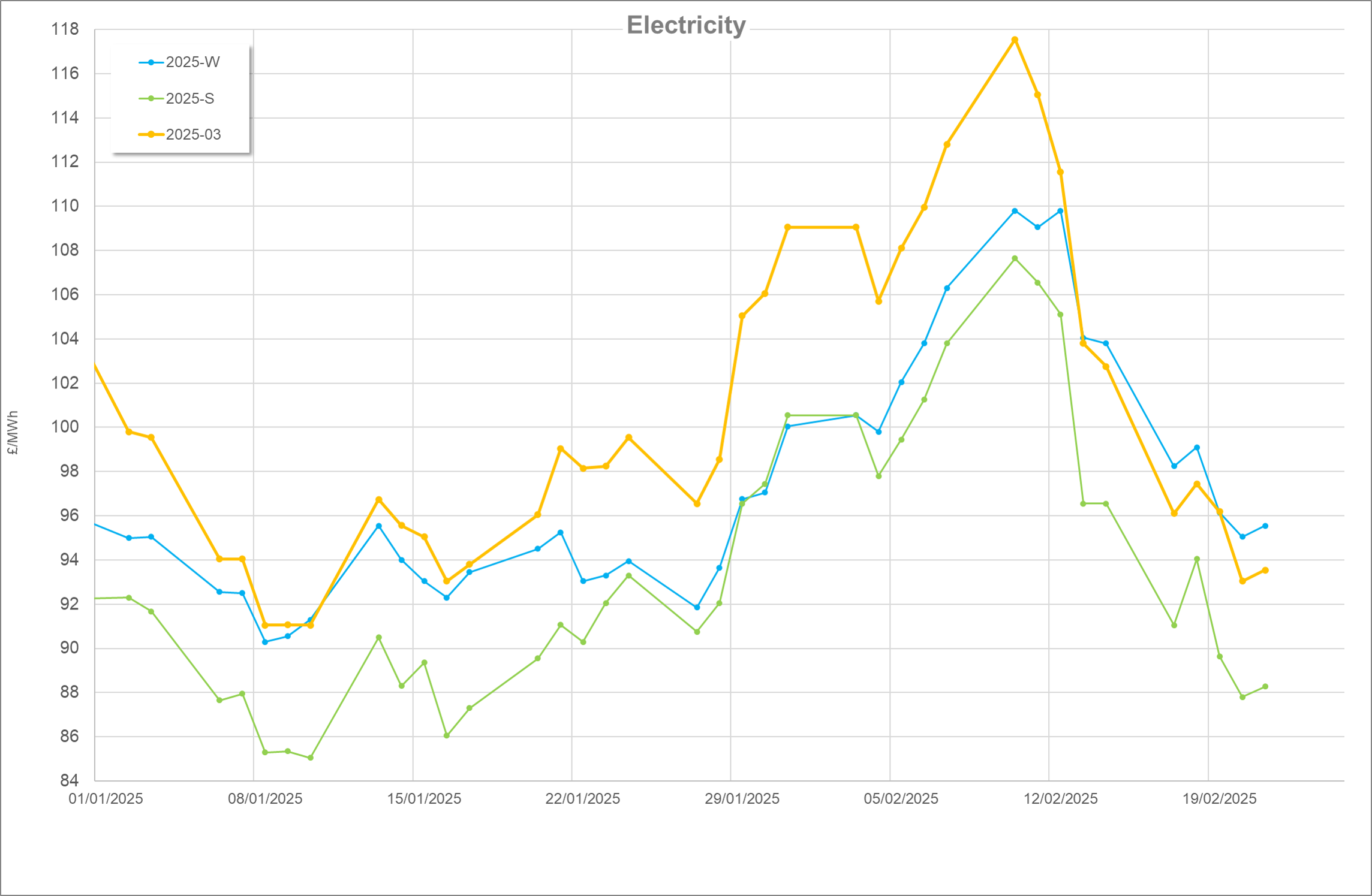

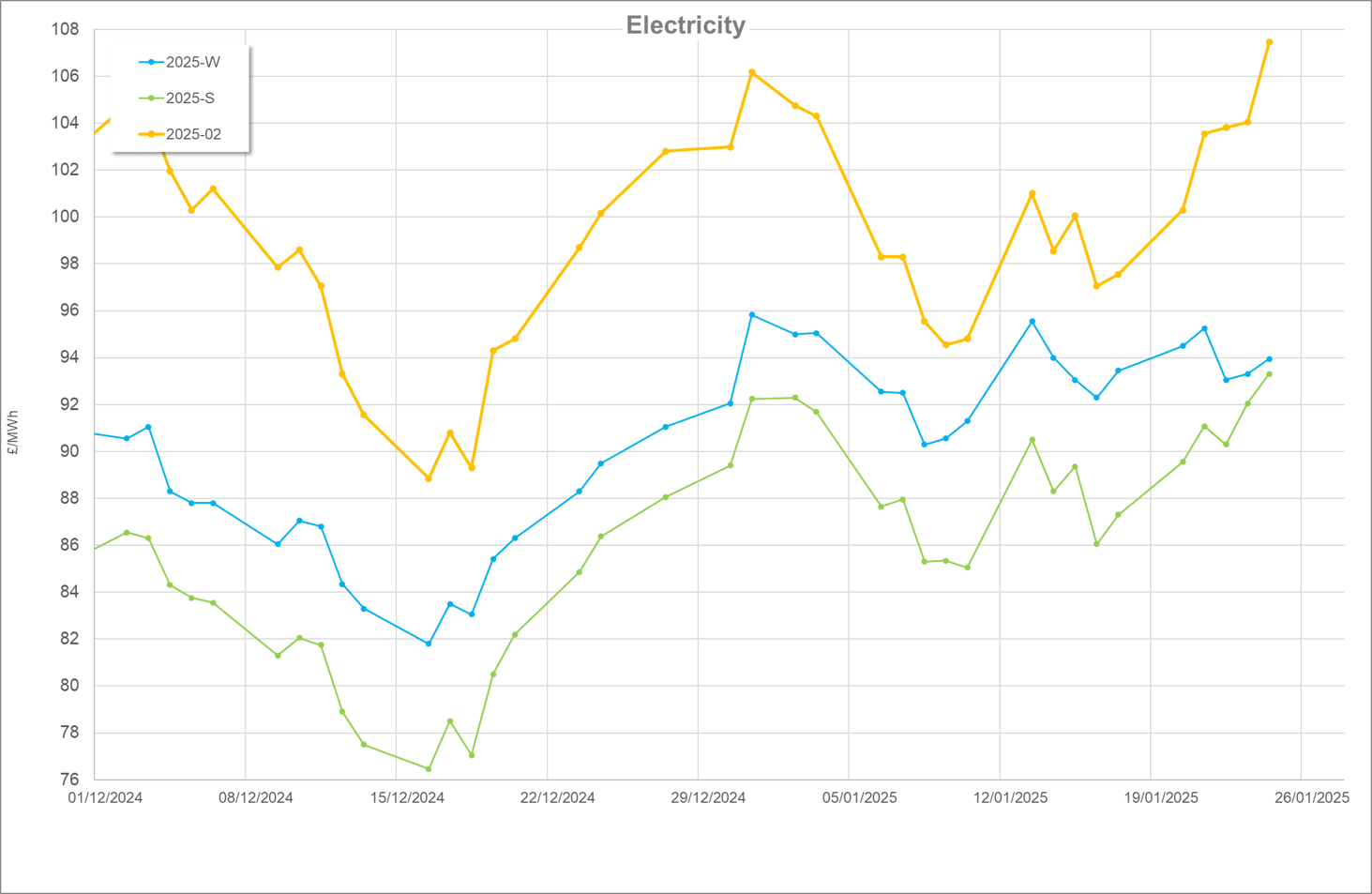

Historically, it has been a clear benefit to operate CHP when possible. However, the trend in the energy market over the last 12 months has been negative for CHP operation (relatively low available electricity price compared to gas, particularly during the day when CO2 is needed). Alongside CHP producing higher levels of greenhouse gas emissions and the impacts of blending hydrogen into the gas grid, the way that CHP is operated in the future likely must change.

Future of CHP

CHP is an efficient way to produce heat and electricity simultaneously. Due to this, it’s benefitted from schemes such as the CHP Quality Assurance scheme (CHPQA), which allows participants to benefit from Climate Change Levy (CCL) reductions. However, with the UK’s Net Zero agenda, these kinds of benefits may not last.

As more low-carbon electricity generators are connected to the national grid, the average emissions factor decreases. Using 2024 reporting factors, the following table shows the relative emissions for satisfying 1MWh of electricity demand via CHP whilst cogenerating heat, and the emissions of importing the power and using boiler to produce the same heat.

| 1MWh Elec | 1.1MWh Heat | Total | |

| CHP | 435.5 | 435.5 kg CO2e | |

| Grid & Boiler | 207.1 | 217.7 | 424.8 kg CO2e |

This represents the most favourable conditions for CHP operation, where all heat is required on site. When not all heat can be used/stored, or when CHP is running solely for electricity/ CO2, the emissions comparison becomes significantly worse.

The cost of importing electricity from the grid currently makes grid & boiler less beneficial financially, however, that may not always be the case. If the government is serious about reducing emissions in climate-controlled growing, this balance may be addressed. This will also have the side effect of halving the CO2 produced on site.

For context, the removal of CCL relief would lead to an increase of around £18.5 per MWh electricity generated.

Energy Market

The largest factor holding back alternative heat generation technologies is the cost/value of electricity. Having CHP not only allows a site to offset expensive grid import, but having the ability to export power during peak price periods and engage in programmes such as the Capacity Market can be a very lucrative and necessary diversification.

Assuming one can obtain a grid connection with sufficient capacity (which is in no way guaranteed), the issue with importing electricity is twofold: unit cost and connection cost. As covered in a previous article (Non-Commodity Costs and Combined Heat & Power Operation), the simplistic spark spread for generating electricity has worsened, making imported power more competitive with self-generation (when electricity is the only desired product). However, the standing/capacity charges associated with holding an electricity connection have become prohibitive.

Between 423-1,000kVA grid connection puts a site into an HV Band 2 classification, which comes with a fixed charge in the order of £30,000 per year. Those who are unfortunate enough to have a capacity over 1,000kVA fall into HV Band 3, which roughly doubles that annual cost.

These costs make electrifying heat very unattractive. It has been stated that the magnitude of these charges is not permanent, they are intended to be used to invest into grid infrastructure improvements, however, with long-term plans to electrify both the heating and transport sectors, it is likely that the grid infrastructure will always need improvements.

The most likely scenario, in my opinion, is that additional costs will be levied against gas import either as a fixed price or increased unit price, rather than decreasing electricity connection costs.

Hydrogen

In a previous article, we went into detail regarding the viability of hydrogen production in horticulture, concluding that it did not currently make financial sense.

It is likely that hydrogen production continues to be unviable on a small scale, however there is greater potential for large-scale hydrogen production in energy storage and injection into the gas grid. This would affect horticultural CHP users in two ways, likely gas cost will increase to pay incentives to hydrogen producers, and any natural gas burned on site will deliver less CO2.

Although the UK government has made the strategic decision to support blending up to a maximum threshold of 20% hydrogen by volume, this would require upgrades to both the transmission & distribution network as well as end user infrastructure. A 5-10% blend should be possible immediately.

Without speculating on the additional costs which may be incurred, the following table outlines how much gas must be burned to generate 1 tonne of CO2, with different hydrogen blends.

| Hydrogen Blend | Volume (m3) | Energy (MWh) | Current Cost[1] |

| 0% | 489 | 5.47 | £168 |

| 2% | 499 | 5.50 | £169 |

| 5% | 515 | 5.54 | £170 |

| 10% | 543 | 5.63 | £173 |

| 20% | 611 | 5.83 | £179 |

If 20% hydrogen by volume is blended into the grid, this would lead to around a 7% increase in the energy required to generate 1 tonne of CO2. However, since hydrogen has a lower volumetric energy density, the volume of gas required increases by 25%.

Assuming that gas will still be paid per energy unit rather than volume, this would lead to an increase in gas cost of 7%. Depending on the markets, this may be enough to make pure CO2 a more attractive option.

Maximising Outputs

Although it is already the case now, future CHP operation will rely more heavily on leveraging the maximum possible efficiency out of the system. This means extracting value from each output of the system; excess heat destruction may not be a viable strategy, potentially requiring larger thermal stores, absorption chillers, or other heat-intensive diversification.

Smaller capacity CHPs targeted at the electricity demand of site, rather than export, may be more viable. And co-location of CHP with electrical heating such as heat pumps can avoid expensive standing charges by operating in island mode, cheaply delivering both heat and CO2 (likely requiring top-up with pure). The table below outlines the current outputs and cost for operating a 1MW heat pump using the grid and CHP.

| Elec Import (kW) | Gas Import (kW) | Heat Production (kW) | CO2 Production (kg/hr) | Cost (£/hr)[2] | |

| Grid | 250 | 0 | 1,000 | 0 | £45 |

| CHP | 0 | 600 | 1,270 | 109 | £18 |

Not only does a small, dedicated CHP allow for lower operational costs, but it can deliver some CO2, and by operating on island mode it can eliminate the need for an additional 250kVA connection capacity.

The relative costs of electricity and gas can certainly change, but this example is one way that medium-term CHP operation is likely to be viable.

[1] 90p/th

[2] 90p/th gas, £180/MWh electricity (including commodity and unit-based non-commodity) costs

Written by Eirinn Rusbridge