First published May 2021

Learn how you can better manage your irrigation system to improve energy and water use efficiency and produce better, healthier plants quicker, often with relatively small investments in time and technology.

Quick links:

- A balanced perspective

- The seven ‘C’s of irrigation energy efficiency

- Irrigation energy efficiency: Control

- Irrigation energy efficiency: Core equipment

- Irrigation energy efficiency: Containment

- Irrigation energy efficiency: Counting

- Irrigation energy efficiency: Care, Cost and Create

A balanced perspective can bring real benefits

The energy efficiency of irrigation systems is perhaps not the biggest focus for most growers. Irrigation energy use will seldom represent more than 5% of total use, so it needs to be put into perspective in terms of what can be achieved through efficiency and how it fits in with the overall business energy strategy. The primary value of irrigation is in supporting profitable and healthy plant growth. This should be the overriding issue when it comes to managing systems.

That said, where energy use can be reduced, and the associated implementation costs produce a good return on investment, then it makes good business sense to pursue these.

There is another upside to running more efficient systems in that, the chances are that water delivery will be better targeted and controlled and this will have a positive effect on plant performance and disease control. It will also save on water costs.

Technology in irrigation has progressed steadily over the years. It’s gone through a long period of evolution, not revolution, and consequently, there’s been few ‘silver bullet’ solutions to deliver a super-efficient system. In practice being efficient is about looking through the various possibilities for saving and implementing cost-effective measures in a methodical way. As such, energy efficiency practices are largely straightforward and mostly based on common sense.

The seven ‘C’s of irrigation energy efficiency

There’s a useful set of energy efficiency guidelines called the Seven ‘C’s which offer an ordered way of looking at how any system can be improved to lower energy use and costs. The ‘C’s in question are Core Equipment, Control, Containment, Counting, Care, Cost and Create.

Using these concepts helps to set out some of the opportunities for improvement.

There are several ways that irrigation can be better managed to improve energy and water use efficiency, including refinement of existing systems, investing in new more efficient designs and using decision-based tools to irrigate based on multiple sensor and information inputs. Increasing efficiency will undoubtedly save energy and water but it can also produce better, healthier plants quicker and in many cases with relatively small investments in time and technology.

Irrigation energy efficiency: Control

What are the basic control requirements and what are the advantages of more advanced systems and sensors?

Control is a critical issue for both energy and crop performance reasons. The most basic systems should offer accurate timed control of the various zones of an irrigation system.

More advanced systems start to integrate with sensors like soil moisture content, solar radiation, weather and soil temperature and are often integrated with the glasshouse climate control system. There is a big human factor here, in that all these aspects depend on some level of interpretation to achieve a successful irrigation schedule (this is discussed under ‘Care’).

‘Precision’ systems are a bit of a buzzword at the moment. These real-time sensor driven systems which have multiple inputs and knowledge-based algorithms, can tweak irrigation input and make a big difference to irrigation performance.

Experience shows that energy and water typically have the least impact on the viability of precision systems since energy and water costs only make up a small percentage of overall production costs. The big benefits come from increased growth rates, reduced production times and reduction in losses through reduced root disease pressure.

Irrigation energy efficiency: Core equipment

We consider the primary energy drivers of the irrigation system, the volume of water it moves and the pressure against which the pumps have to operate. How do you reduce pressure and how can your choice of pump help?

At this stage, it’s worth considering the primary energy drivers for irrigation systems.

A system’s energy use is directly proportional to the volume of water it moves and the pressure against which the pumps have to operate. Double the volume or the pressure and the energy use in delivering the water also doubles. So, it follows that if either of these factors can be reduced then less energy will be used in the system.

The volume of water use is critical, and this is looked at in a little more depth when we consider ‘Containment’ and ‘Control’ in the Seven ‘C’s approach.

The three primary factors involved in reducing pressure

Reducing pressure is linked to three primary factors:

- Connecting pipe size and the pressure drop through the delivery system. If the velocity of the water through the pipes and joints is too high, then water pressure losses are high. Likewise, if filters are too small or become blocked then more energy is needed to overcome them. The important thing here is to measure the pressure in the system at different points to determine where pressure is being lost. Any more than 20% might be seen as excessive.

- Final Delivery System. There are big differences between systems which use spray nozzles and those which provide drip irrigation. Generally, spray systems have pressure requirement between four and ten times greater than drip delivery systems. This relates directly to energy use, so the choice of the system at the design stage has obvious long-term energy implications.

- Primary Feed System. Here we are concerned about the choice of pump and how it can work flexibly with the final delivery system.

Pumps: points to consider

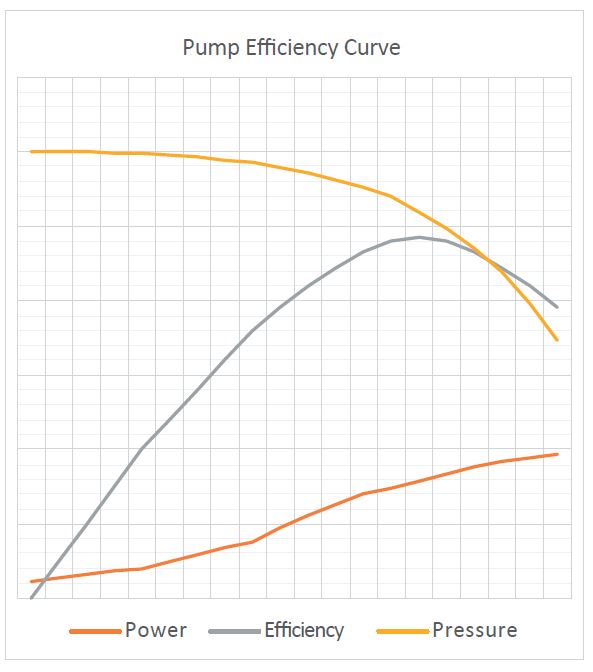

- Pumps must have a characteristic such that maximum efficiency is reached at around the pressure and volume required by the system. If pumps are badly specified, they may be operating considerably below their efficiency ‘sweet-spot’. So, for instance, using a high-pressure pump on a low-pressure system may still deliver the volume of water required, but energy use per unit of water delivered will be higher than it should be. Check your system operating pressure against the manufacturer’s efficiency curve for your pump to see what efficiency you are achieving.

- Pumps should be fitted with the most efficient motors. Electric motors have always been pretty efficient but new pumps are marginally better than older designs (probably 2 or 3% better) and, over the life of the pump, the cost savings from the high efficiency motor type may be worth an upgrade. For example, a 11kW pump running 30% of the time will cost £4,500 per annum. A 3% saving would be £135 per year giving £2,025 savings over the expected lifetime of 15 years. Note costs used are correct as at October 2019.

- Pump systems must be able to respond to changing volume and pressure requirement caused by different levels of irrigation and changing irrigation location. For a ‘fixed speed’ pump, this is a big ask, and in the past, the only way to deliver this has been through the use of pressure relief valves to ‘bleed-off’ some of the extra pressure or volume delivered by a pump with restricted output requirement. Although this is effective it is not energy efficient. It’s now commonplace to deal with this problem by using variable speed pumps (with inverter drives) which are modulated to deliver a fixed system pressure. This can have a really big effect on energy use. On large irrigation systems research has shown a reduction of up to 50% in annualised running costs can be achieved.

Irrigation energy efficiency: Containment

How to get most of the water in your irrigation system to the plant and avoid losing it through evaporation, overspray, interception loss, and bad uniformity.

Most watering systems are notoriously bad at getting water in the irrigation system to the roots of the plant. Take a spray irrigation system, for instance, water is lost in several ways:

1) Up to 25% of delivered water will evaporate from the droplets and the surface of the plants and soil.

2) Water will be lost through ‘overspray’ at the edges of an irrigated area.

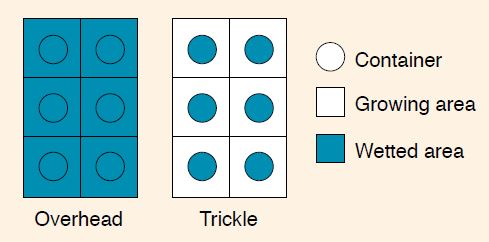

3) Water will be lost between plants especially if they are in pots. This is known as the interception loss. Interception efficiency gives a measure of the water reaching the plant pot and is calculated as:

% = Container top areas ÷ Container ground area x 100

It can often be as little as 30%.

4) Water is lost through bad uniformity. Here, overwatering takes place to compensate for pockets of reduced water delivery.

All these things add up to a large amount of waste, resulting in delivery system efficiencies (accounting for loss of water and wasted electricity) of as low as 15% in some cases and rarely better than 40%.

The additional cost of this is not just in energy. There is the water cost to consider as well as filtration and treatment costs as well as, in a lot of cases, fertilizer and herbicide.

How to improve water delivery efficiency

There are lots of things that can be done to improve delivery efficiency (water containment) but, in many cases, it is an exercise in painstaking incremental improvement.

Here are a few suggestions:

- The most effective and far-reaching water delivery improvement that can be made by going for direct trickle irrigation. This is only suitable for some types of crop and can lead to problems in maintaining good flow in all pipes. However, from an energy and water utilisation point of view, it can make a massive difference through direct water delivery and much lower system pressures. It’s quite possible to see energy efficiency improvements of 90% or greater by moving to trickle irrigation.

- Boom systems are marginally better than fixed nozzle systems as they take one dimension out of the uniformity issue. However, they must have well-controlled delivery as they progress along a bed.

- With spray systems, nozzle selection and positioning are very important, as this will determine uniformity and the amount of over-spray. Doing regular measurement of uniformity and making adjustments accordingly does help. Larger droplet size will reduce evaporation.

- Placing plants at minimum spacings will maximise the interception efficiency. This might mean more labour in respacing containers later in the growing period, but it can help with irrigation.

- Maintenance is important to make sure everything is working as intended and leaks located and repaired.

Irrigation energy efficiency: Counting

What aspects should you monitor in order to manage your irrigation system effectively?

Effective management of irrigation will come from disciplined measurement and recording and taking action as a result of the information gathered. Aspects to monitor are:

- The System pressure – which will impact on uniformity and overall system efficiency.

- Uniformity – through water distribution sampling.

- Water use – install and read water meters to detect overuse and signal possible leaks.

- Energy use – electrical sub-metering of pumps is useful especially when linked to water use. Here a specific energy use per m3 of water delivered (kWh/m3) will signal changes in underlying system efficiency.

- Climate control computer records – running times of pumps and operation times of valves can be plotted and give a visual record of how and when the system is operating.

Benchmarking this data should be done against other sites you own or manage or even different years. You should take care to compare like for like figures as individual organisations’ energy consumption will vary greatly.

Irrigation energy efficiency: Care, Cost and Create

Why irrigation systems need you to care enough to use them properly plus a look at what role cost plays and why it pays to be inventive about where your energy comes from.

Care

Even the best systems in the world with the most sophisticated control and monitoring will only work if someone cares enough to use them properly.

This is especially important with irrigation because automatic sensing and control can only take you so far. Good irrigation management will always require a generous measure of knowledge, experience and motivation to get things right.

The impact on energy may be important but crop performance is the main issue here. A host of additional problems may be magnified through poor water management, including algae and pest-management problems, leaching fertilizers and increased disease pressure.

Individual motivation comes through training and good staff management to lead workers to understand the importance and impact of doing things properly.

Cost

Cost is not in itself an efficiency issue, but it drives the need for better efficiency and indicates the highest priority issues and those which, although desirable, might not be justifiable economically. It’s, therefore, important to analyse what improvements might cost and try to estimate what impact they might have on value and output. Only then can you derive a rational plan for improvement.

Create

Be inventive about where the energy comes from. If systems can avoid the use of bought-in energy, then energy efficiency may no longer be quite as relevant.

Some examples of this might be:

- Where sites are hilly, water storage can sometimes take place at a higher elevation to than the growing site, resulting in the head pressure of the storage being enough to drive the irrigation distribution system.

- Use of solar and wind powered pumps, perhaps in conjunction with gravity fed systems, can provide the energy needed in the irrigation distribution system. Systems with gravity water storage take the time pressure off renewably powered pumps, so they can work when the solar or wind energy is available and effectively ‘store’ the water pressure energy over an extended period.