First published May 2011

Learn what practical changes to make to improve the integration of screen and vent controls with your lighting operation.

Quick links:

- A practical case study

- What are the potential problems to using lights under screens?

- How to correct the problems

- How to improve the effectiveness of greenhouse screens

A practical case study

Because supplementary lights also produce heat they can have a sudden impact on the temperature balance of a greenhouse when they are turned on.

Get your control strategy right and the ‘waste heat’ from the lights can make a useful contribution to the heating needs of the greenhouse.

On the other hand, get it wrong and the heat can be a headache which has an adverse effect on both the greenhouse environment and your energy costs.

It is particularly important to get the interaction between lighting operation and screen and vent control right, so this update looks at the changes the GrowSave team made at Humber VHB’s West End site.

What are the potential problems to using lights under screens?

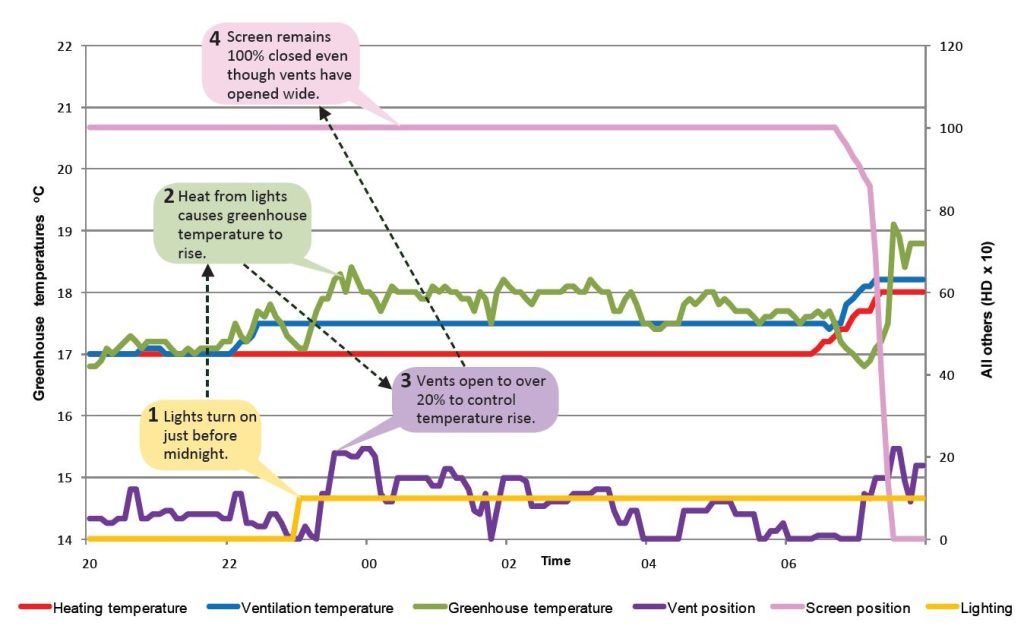

What happens when the lights turn on and when the screens open in the morning.

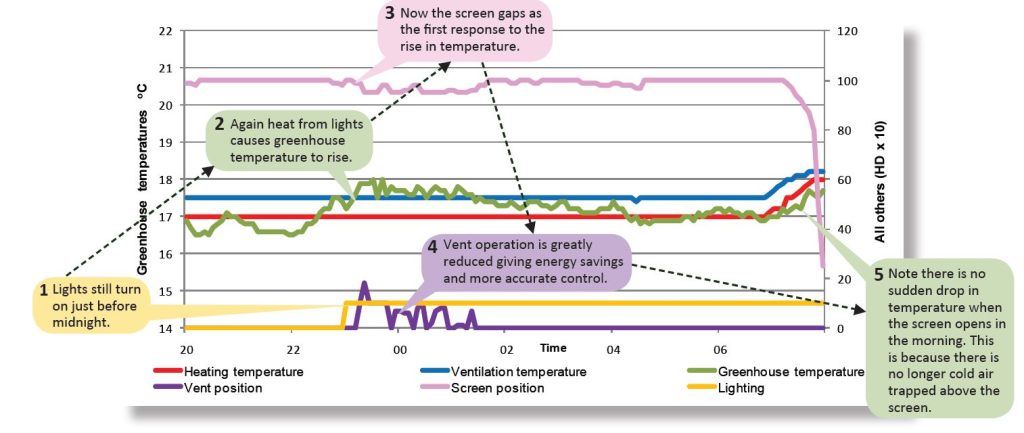

The graphs in Figure 1 and Figure 2 show what can happen when screen and vent controls are not correctly integrated with lighting operation.

The main issue here is that the vents are open and cold air traps above the fully closed screen. This leads to potential energy waste and problems when the screen opens the following morning.

Once the screen is opened in the morning, the cold air which has been trapped above it falls into the greenhouse causing the temperature to drop dramatically. Whilst this can be overcome by operating the heating system, unnecessary energy waste occurs because of the rapid change in temperature and the inability of the heating and control systems to accurately restore the required temperature.

How to correct the problems

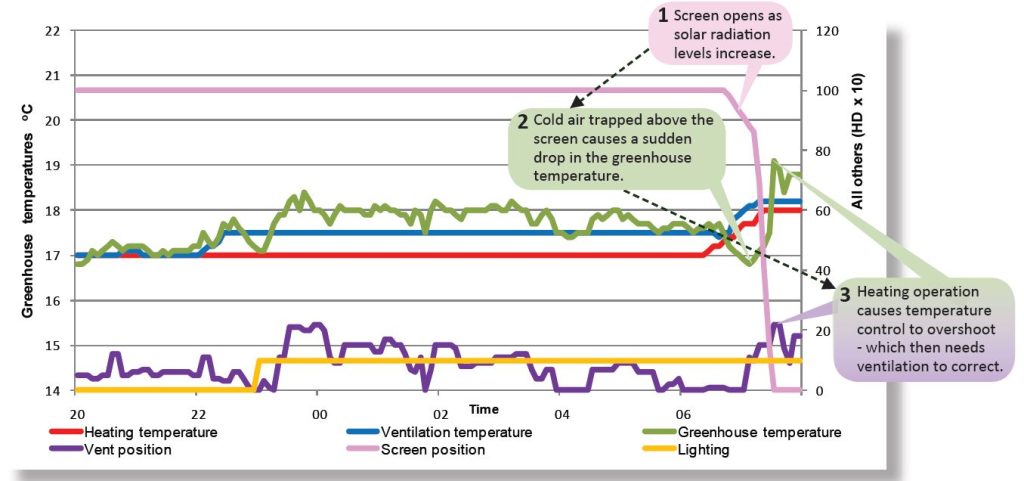

What happens when you gap the screens before opening the vents.

The golden rule for controlling screens is to gap them before you open the vents. The graph in Figure 3 shows the result when this approach was applied on our Focus Nursery.

The control settings used to achieve this result were to start to gap the screen when the greenhouse temperature was 0.2oC below the vent temperature. The screen gap was then increased until it reaches a maximum of 5% when the greenhouse temperature was 0.5oC above the vent temperature.

How to improve the effectiveness of greenhouse screens

Learn how to use greenhouse screens to save energy, control humidity and achieve a uniform growing environment.

Read more about improving the effectiveness of greenhouse screens