First published May 2020

An in-depth look at how air movement affects the greenhouse climate and the crop, how you can generate, measure and manage it effectively, and how to calculate the economic return of using pipe heat and fans.

Quick links:

- Why is air movement important

- How to achieve energy balance within the crop

- How to identify a problem

- How to generate air movement

- How to calculate economic return

- Theory vs practice

A key climate control tool

Optimising production methods is one of the aims of many greenhouse growers. Determining what makes an optimal climate for crop quality and production, however, can be challenging, and it’s certainly worth bearing in mind that what feels comfortable to a person may be less than ideal for a crop. Furthermore, each type of plant will have its own requirements and characteristics in terms of the environment it can thrive in. An important part of achieving that environment is air movement.

Why is air movement important?

How does air movement help to maintain an active and homogeneous climate in the greenhouse and what are the benefits for the crop?

Air movement should be seen as a tool to help maintain an active and homogeneous climate. This can lead to a number of benefits including:

- Uniform humidity

- Uniform temperature

- Assisting transpiration

- Reducing condensation and disease risk

- Achieving uniform plant growth

- Efficient use of energy

One of the major benefits of good air movement is a reduced risk of disease. A build-up of moist air around the crop can lead to condensation forming on the plant if its temperature falls below the dew point. This can occur as a result of radiation exchange between the plant and a cold sky, even if the greenhouse air temperature is above dew point.

Importantly, this can happen whenever there is a net outgoing radiation exchange (i.e. more energy going out than coming in), which can occur both during the daytime and at night.

By moving air around the greenhouse, humidity and temperature can be evened out to much more desirable levels. This allows for more predictable humidity control. A uniform climate is also likely to result in uniform plant growth, meaning fewer rejects and, potentially, easier harvesting.

Furthermore, for greenhouses which experience significant temperature variations, achieving an even climate will reduce overcompensation effects, meaning energy consumption can be reduced.

How to achieve energy balance within the crop

A closer look at the effect of air movement on plant transpiration and evaporation.

The energy balance of the crop is strongly influenced by temperature, humidity and air movement.

Transpiration

The following formula demonstrates the energy balance with regard to transpiration:

E = (R – G) – Q

E is transpiration

R is incoming radiation absorbed by the canopy

G is outgoing radiation

Q is energy transferred from the plant by convection

Transpiration from a leaf is defined as water transfer through the stomata. It is caused by absorption of radiation and is only true if there is light. The driving force is vapour pressure difference (VPD) between the water inside the leaf and the air surrounding it. The amount of transpiration is related to stomata opening multiplied by VPD.

From the formula it can be seen that if the convective exchange (Q) increases, there will be a decrease in transpiration (E) since there is less energy available for it. Depending on the temperature of the air, air movement can either increase or decrease convective energy transfer. If the air blown around the canopy is colder than the leaf, the energy transferred from the plant by convection will increase, meaning a decrease in transpiration. If the air is warmer, however, energy will be transferred to the plant, hence transpiration will increase.

Therefore, while it may initially seem counterintuitive, it is possible to reduce the transpiration of the plant by increasing air movement, if the air is colder than the leaf temperature.

Evaporation

The second way to exchange moisture is by evaporation through the surface of the leaf. This is also driven by vapour pressure difference, but now the stomata can be closed and no absorption of energy is needed other than for transpiration.

It is assumed that the leaf is saturated, so the leaf temperature determines the vapour pressure in a steady state situation. The vapour pressure of the surrounding air dictates the amount of evaporation. The leaf absorbs energy from the surrounding air and from radiation sources such as a heating pipe or a warm floor.

This is the basic system in the dark and now air movement will reduce the build-up of water vapour in the boundary layer of the leaf. As long as the vapour pressure of the greenhouse air is lower than in the boundary layer, air movement will increase evaporation.

Replacing colder air in the boundary layer with warmer air will increase evaporation, since extra energy is being supplied to the leaf; the opposite is also true.

How to identify a problem

How to measure air movement to assess the evenness of climate across the greenhouse and crop.

Before investing in expensive equipment, it is worth determining if you actually have a problem. The chances are, if you don’t use anything to generate air movement, there will be some degree of unevenness in terms of climate across the greenhouse and crop.

How to measure air movement

Measuring air movement can be tricky. Without sensitive and expensive equipment, measurement accuracy at low velocities can be unreliable. Close to a fan, for example, air velocity will be high, while at crop level, it could be significantly lower. The optimum amount of air movement should also be considered. Rather than measuring volume flow or metres per second, a proxy measurement could be more effective, e.g. uniformity of temperature or humidity across the greenhouse.

To know exactly what the current situation is and whether or not it has improved, some measurements are needed. In many situations there can be a significant difference between the microclimate and the measuring box reading, not because of erroneous data, but because the climate is actually different at these locations.

Using just one measuring box per zone is simply not enough. Instead, a matrix of sensors should be used to give a good resolution of the growing area.

Temperature can be used as a proxy for air movement and can help to identify problem areas. By creating a ‘heat map’, it is much easier to visualise what is going on than by relying on measurements alone. In addition, a thermal camera can be used to measure the temperature of a fruit or head of a plant, as this may be considerably different from leaf or air temperature, and can lead to serious problems later on.

Once the issue has been understood, a solution can be considered. Industry experts advise a target maximum variation of 1°C vertically and horizontally throughout the greenhouse, which can be achieved with readily available equipment and careful planning.

How to generate air movement

A look at some traditional and alternative methods of air movement and their relative merits.

Without using any mechanical devices, some air movement will occur through natural convection. Warmer air is less dense than colder air, hence cold air sinks and warm air rises. Temperature differences across a greenhouse can arise for various reasons, such as pipe heating, incoming radiation from the sun, outgoing radiation (i.e. heat loss) from the greenhouse, or transpiration of the crop.

However, relying solely on natural convection to drive air movement is unlikely to result in a homogeneous climate. This section considers some traditional and alternative methods of air movement and their relative merits.

Pipe heat

Some growers use pipe heating to create convection currents. For those with grow pipes or rail heating, the warm air will rise through the crop and can help to carry moisture away from the plant, locally reducing relative humidity. However, this can be an expensive method of generating air movement (see How to calculate economic return) especially if the heat is not required; relying on convection to stimulate sufficient air movement to keep the climate active and homogenous is not advisable. Instead, air movement through the use of fans is much more effective.

Horizontal fans

Different fan setups are available, although the suitability of each will depend on the type of crop. An important consideration should be the height at which the air moves and how this interacts with the crop.

A horizontal fan setup can be regarded as the conventional option for generating air movement. These fans tend to be mounted above the crop and operate by moving air in a horizontal plane to create a circulation pattern. This can be a good option for a tall crop, as it will stimulate airflow through the plants, but it is not the most effective solution for ornamentals at ground level.

Rule of thumb: Aim to recirculate the total volume of greenhouse air twice per hour using around 20 fans per hectare. Before purchasing, refer to the fan’s specification sheet to determine if it can move the required volume of air at the desired rate.

Vertical ducts

Instead of moving air across the greenhouse horizontally, which can result in layers of air moving at different speeds, a vertical setup can be a better option for making sure air penetrates the crop. In addition, air is moved a shorter distance, meaning a lower power fan can usually be used.

A ducted system, consisting of a fan at the top and a long plastic tube which directs air towards the ground, could be a good option for bench crops. However, the blown air can stir up dust on the ground and can result in localised air movement, which may have an adverse effect on a ground crop by stimulating too much evaporation, thus drying out the plant.

Vertical fans

Horticulture-specific vertical fan designs, such as the Nivolator, disperse air in a conical flow, giving a wide range of coverage. Air is drawn from both above and below the fan, creating a local circulation pattern.

Depending on the height at which the fan is mounted, each unit can cover a diameter of around 15 metres. While this can mean more fans are required than in a horizontal setup, air can be directed exactly where it is needed.

Importantly, the aim should always be the most effective solution to promote air movement for a given crop.

Air tubes

Another option is to use long plastic tubes incorporating a fan underneath the crop. The tubes have holes along their length, allowing air to escape. Consequently, this results in some air movement around the tubes. However, the nature of the design usually means a fan at one end of the tube, which can lead to a drop-off in airflow along the tube, with the far end potentially emitting much less air than the end closest to the fan.

How to calculate economic return

Two example scenarios for stimulating air movement and controlling the climate: one scenario uses pipe heat, the other uses fans.

For many, the nature of business means that any investment in new technology must demonstrate an acceptable economic return. While it can be hard to accurately quantify the financial benefit of improved crop quality or projections of increased yield, it is much easier to consider energy costs.

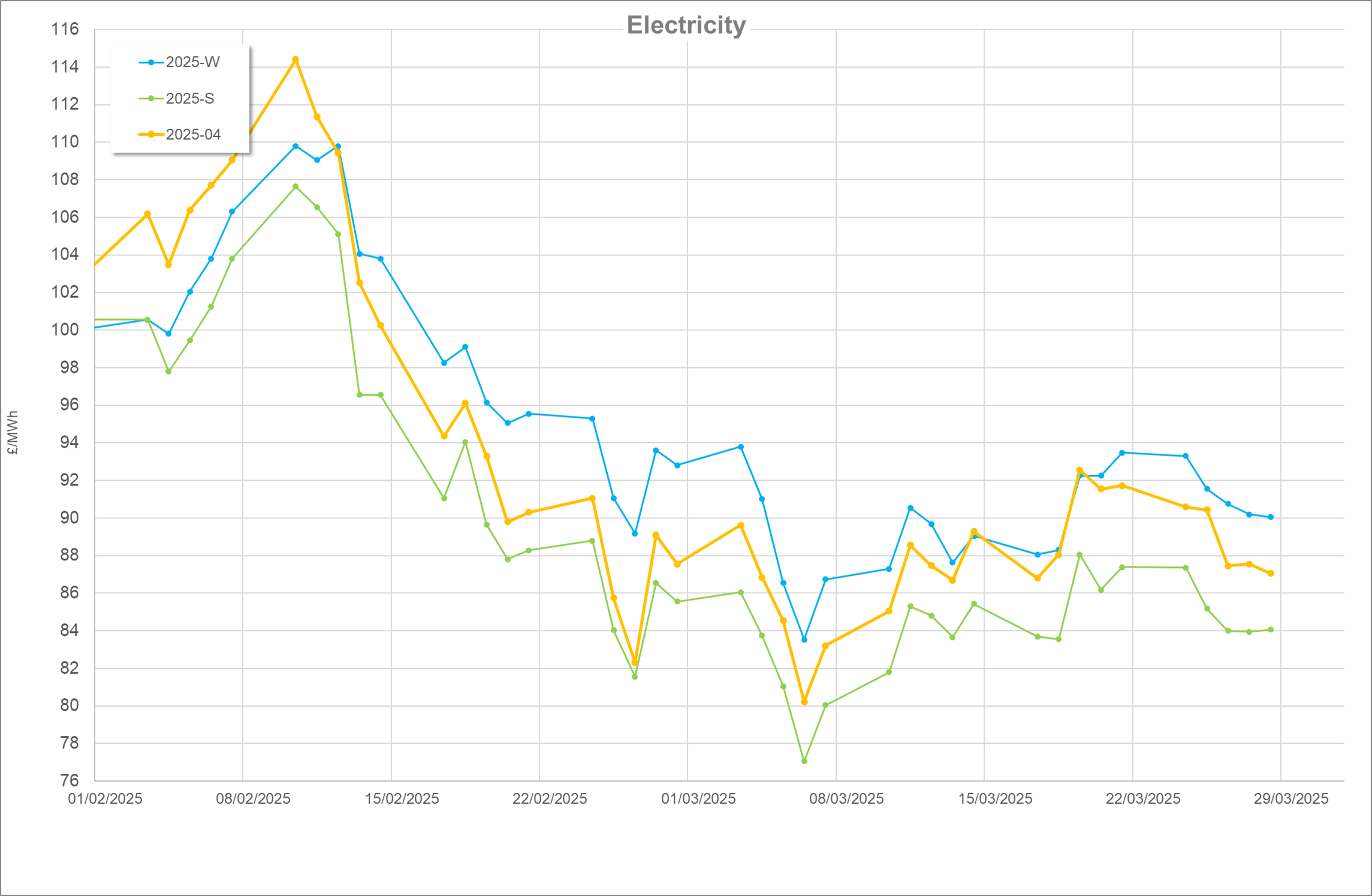

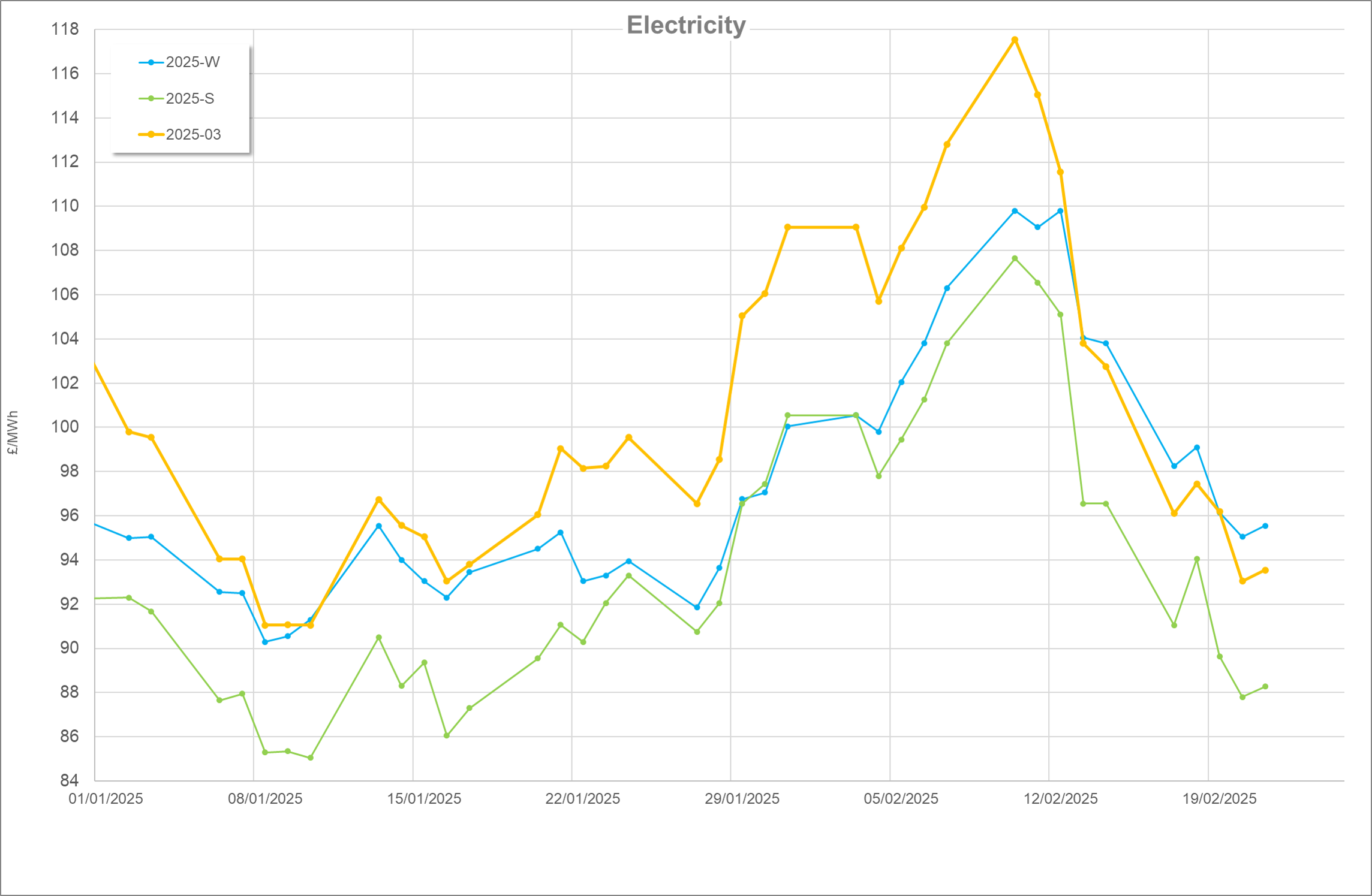

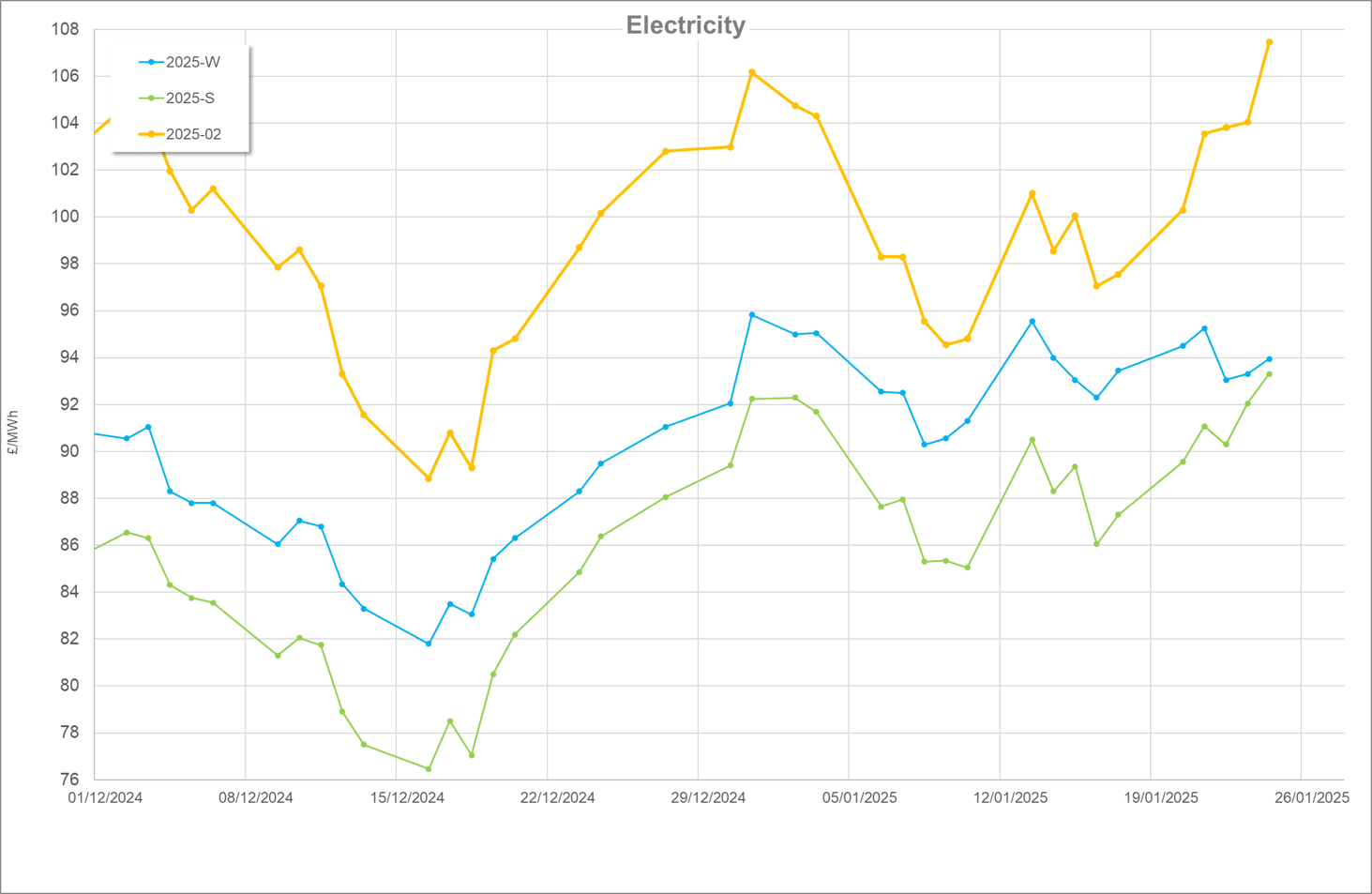

Here are two example scenarios for stimulating air movement and controlling the climate: one scenario uses pipe heat, the other uses fans. Costs used are correct as at May 2019.

Pipe heat

Scenario: Pipe heat is used for humidity control every day for six hours. The pipe is kept 5°C warmer than it would otherwise be for heating alone, requiring an extra energy input of 15 W/m2 for a 1.25m length of 50mm pipe per square meter. The cost of fuel is £0.02/kWh.

Increase in pipe temp: 5°C

Additional energy input: 15W/m2

Running hours: 6 hours/day x 7 days/week = 42 hours/week

Energy cost: £0.02/kWh

Cost of air movement:

15/1000 kW x 10,000 m2 / Ha x 42 hours/week x £0.02 kWh

= £126 per week per Ha

Fans

Scenario: An arrangement of 20 fans per hectare is used to create adequate air movement. Each fan is rated at 250W and runs for 10 hours a day. The cost of electricity is £0.12/kWh.

No. fans: 20 per Ha

Power consumption: 250 W/fan

Running hours: 10 hours/day x 7 days/week = 70 hours/week

Energy cost: £0.12/kWh

Cost of air movement:

20 Ha x (250/1000) kW x 70 hours/week x £0.12 kWh

= £42 per week per Ha

Theory vs practice

The key points to consider when putting the theory into practice and deciding between pipe heat and using fans for air movement.

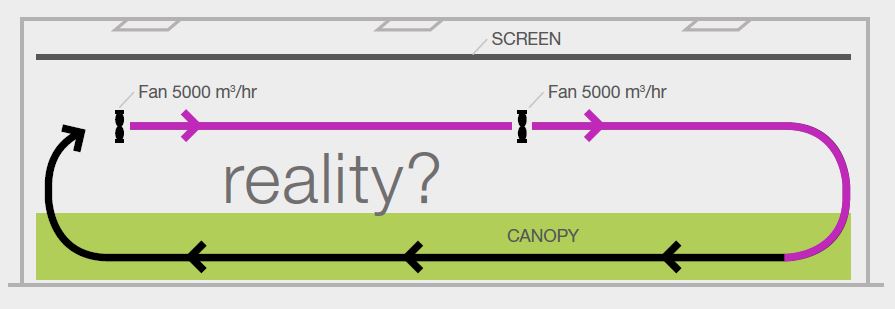

The theory of where air should go based on a particular layout or manufacturers’ claims does not always match up with reality.

Factors such as wind direction or the slope of a greenhouse can significantly affect the flow of air. It can be a good idea, therefore, to visualise how the air is moving.

One effective method is a smoke test. This can often highlight otherwise unseen influences, meaning problems can be identified and remedied, which could be as simple as adjusting fan positioning.

Key points to consider

- The use of pipe heat to stimulate air movement is significantly more expensive than using fans when considered in energy terms alone.

- While there may be an additional capital investment required up front to install a suitable fan setup, additional costs associated with the increased running hours of a pipe heating system, such as boiler servicing and maintenance, should also be considered.

- Based on the energy savings alone, the return on investment of a fan setup could easily make it an economically viable option.

- An increase in energy prices would mean even more significant savings.

- The suitability of the equipment to do the job intended should also be factored in. A well-designed fan arrangement will achieve much better air movement and a more even climate than pipe heating.

In summary

Good air movement is a vital part of creating a homogeneous climate, which can help improve crop quality. While there are various methods for generating air movement, consideration should be given to the most effective solution for a given crop and greenhouse layout.

Fans are often the most economical solution and can reduce energy consumption compared to using pipe heating. The layout and number of fans should be carefully planned, and be prepared to test and adjust the configuration, e.g. using a smoke machine, to ensure optimum results.