First published August 2018

Learn how the techniques of Next Generation Growing (NGG) can help achieve the optimum growing environment, often without the need for big capital investment.

How to provide your crop with exactly what it needs, when it needs it

Next Generation Growing (NGG) is a set of techniques pioneered by Dutch growers to increase glasshouse production efficiency. Typically, good implementation of the techniques described in this technical update has led to a 20% reduction in heat use, but NGG is not only about energy saving.

The key benefit of NGG is the creation of an environment in which the plant thrives so that photosynthesis is maximised under the given light level. This is determined by the right combination of multiple factors, rather than the magnitude of individual factors, such as CO2, relative humidity and temperature.

The principles of NGG focus on providing the crop with exactly what it needs, when it needs it.

Seven key tips

Click on the link to jump directly to that part of the article.

There are seven key tips for Next Generation Growing. In summary they are:

- Achieve an even temperature horizontally in your glasshouse, and ensure the right vertical temperature profile to help keep the plant in balance.

- Keep an active climate by promoting good air movement.

- Improve your humidity control, including accepting more moisture in the air under high radiation conditions.

- Use both vent sides to minimise average vent position and allow venting above closed screens.

- Reduce the radiative cooling effect on the plants by shielding them from clear skies at night.

- Maximise photosynthesis by reducing vents and improving CO2 uptake, misting rather than shading when conditions are too warm.

- Keep the plant in balance in consideration of the ratio of light sum achieved to 24-hour average air temperature.

Many of these tips are interlinked and can be addressed together.

Achieving the optimum climate can be difficult without good monitoring and measuring practices; a good starting point for those new to NGG would be to install sufficient, well-placed measuring boxes. Importantly, the NGG approach does not necessarily require a big capital investment.

Achieve an even climate

Why achieving an even glasshouse climate is the cornerstone of Next Generation Growing.

Keep the climate active

The benefits of creating air movement under closed screens by using fans.

An active climate is essential for nutrient uptake. Keeping the plant active will ensure that calcium, which is only transported by water in the plant and is essential for new cell development, reaches the growing tips. A key technique for ensuring an active plant is to create air movement around the important developmental areas.

In the past, growers have encouraged air movement and plant activity using pipe heat and screen gapping, but NGG takes a different approach. Modern glasshouses are more insulated than ever and, since a basic starting point for NGG is that screens should be closed more of the time, there will be less need for pipe heat. However, without further intervention, closed screens and reduced pipe heat actually result in less air movement and lower plant activity. Therefore, successful implementation of NGG relies on creating air movement under closed screens by using fans.

Improve humidity control

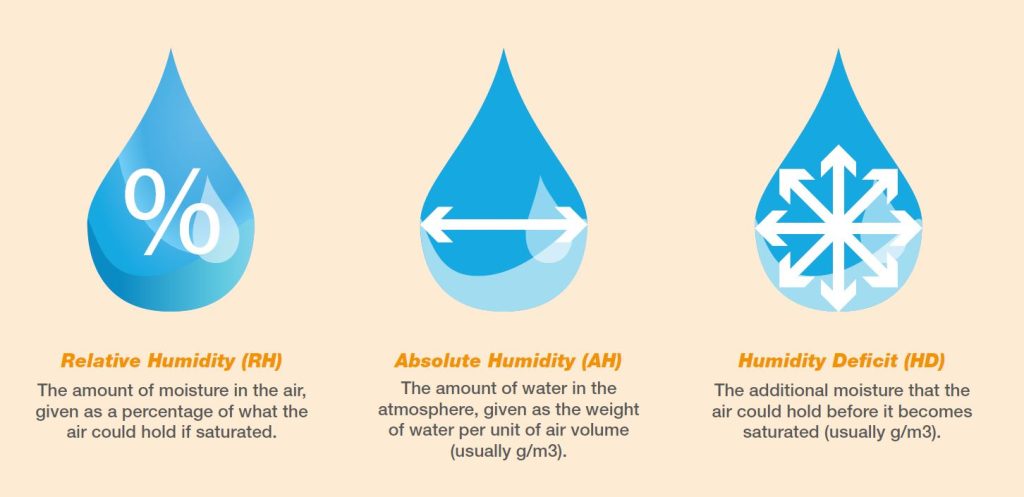

Humidity control can be a complex and often misunderstood concept. There is a myriad of terms, and what these refer to is not always clear. NGG consultants advise growers to familiarise themselves with these concepts, in particular Absolute Humidity (AH). Recording AH alongside existing graph data can help to give a better insight into critical climate events, such as reaching the dew point, and thereby running the risk of fungal disease.

Growers have conventionally controlled humidity under screens either by screen gapping, increasing pipe temperature, or both. However, increasing pipe temperature uses a lot of energy and screen gapping induces unwelcome temperature variations beneath the screen.

Some modern screens allow a better option: using ventilation above the screen. Doing this will not only remove high humidity air from above the screen, but will also draw water through the breathable material, without using any additional pipe heat and without disturbing the even climate below the screen.

The NGG hierarchy for controlling humidity is to vent above the screen first.

If this is not enough:

- Start to gap the screen if necessary, but only with very small gaps of about 1-2 %.

- Use increased pipe temperature as a last resort.

Additional tip: To ensure that the new NGG humidity strategy is implemented correctly, an extra measuring box should be installed for temperature and humidity above the screen.

Vent on both sides of the glasshouse ridge

How to use ventilation above the screen to control humidity.

Combatting variations in the glasshouse climate is the cornerstone of NGG.

Prior to the development of NGG techniques, conventional industry practice was to rely mainly on leeside venting to remove humidity and excess temperature from the glasshouse, this being regarded as the safest way to vent.

Above a closed screen, however, as advocated by NGG, large leeside vent angles would be required to exhaust sufficient moisture through the screens. Therefore, it is advised to use windside vents as well, creating more air movement above the closed screen.

One of the early surprises experienced by the growers experimenting with NGG in the Netherlands was how routine deployment of windside as well as leeside vents could have substantial benefits for the glasshouse climate during the day with open screens. This was largely unforeseen by the researchers who developed the scientific background for NGG.

Leeside venting

In the conventional venting method used by most growers, relatively large leeside vent openings are often required to achieve the desired reduction in temperature and humidity. However, large vent openings create little resistance between the inside of the glasshouse and outside. Of course, outside conditions being strongly influenced by wind speed and direction are commonly quite turbulent, which is translated into variations in the glasshouse climate when the vents are open.

Windside venting

In the early days of NGG, some intrepid Dutch growers began to experiment with some windside ventilation. This enabled them to use much lower vent openings than with leeside ventilation alone, thereby creating more resistance between the glasshouse climate and outside.

They discovered that this resulted in much more stable conditions for temperature and humidity in the glasshouse, as well as noticeably higher CO2 concentration, because less CO2 is lost to the outside. Their experience means that most Dutch growers now use both windside and leeside vents, while a few use windside ventilation only, to create a slight over-pressure inside the glasshouse.

An example venting strategy

As with all NGG techniques, the use of venting on both sides can seem like a big step. It is best to begin by using windside ventilation with small openings above closed screens and gradually extend this to venting with open screens as experience and confidence increase.

A general guideline for implementing windside venting is to open the windside vents almost simultaneously with the leeside vents. One strategy may be:

- Up to 5% window position, use the leeside only.

- From 5-30 % leeside opening, let the windside follow with 0-15% openings, in a ratio of 2:1.

- Depending on outside conditions, this ratio can be adjusted. For instance, if there is little wind, or outside temperature is high, this ratio may be increased to 1:1.

- With a strong wind and/or rain, the windside vents must be kept closed.

Control radiative heat loss

How to prevent energy loss via outgoing long-wave radiation (OLR) and maintain essential plant activity.

Under clear night skies, outgoing long-wave radiation (OLR) can be a big contributor to heat loss. In essence, the plant is trying to heat the cold glass, which, in turn, loses energy to the cold sky. Ultimately, the result is a lower head temperature.

According to NGG experts, this will reduce, or completely stop, transpiration, which will affect crucial cell development, as the availability of key nutrients, such as potassium and calcium, is reduced. Lower leaf surface temperatures also increase the risk of condensation and disease.

The use of some relatively inexpensive sensors can help to reduce losses by OLR. A pyrgeometer measures heat loss to the sky between 0 and -125W/m2 (the notation is negative for outgoing radiation). A pyranometer, meanwhile, should be used to measure solar irradiation. Once OLR exceeds solar irradiation, screens should be closed.

The essence of closing the screen is to maintain plant activity, especially in the top of the crop, by preventing energy loss via OLR. A small gap of 10-15% may be useful at the end of the day, around sunset, if it is necessary to cool down the crop for the night. Once the glasshouse has cooled to the desired temperature, the screen should be closed completely.

Maximize photosynthesis

How to keep light intensity, CO2 and temperature all in the correct range at the same time.

Photosynthesis is optimal only when light intensity, CO2 and temperature are all in the correct range at the same time. The Law of Limiting Factors dictates that photosynthesis cannot be optimal if any one of these environmental parameters is low, even if the other two are ideal. For example, when the plant is under such stress that the stomata close, meaning CO2 cannot enter the leaf, photosynthesis will be depressed, however high the prevailing light and temperature may be.

In the glasshouse environment, maximising photosynthesis means:

- Using less ventilation so that the temperatures remain high; stomata stay open due to higher humidity; less CO2 is lost to atmosphere and more is available through stomata.

- Avoiding water stress because of excessively high humidity deficit (HD).

- Reducing the air temperature and, even more importantly, increasing the humidity, using a misting system (adiabatic cooling) rather than shading.

None of this could easily be implemented without control aids now available in the leading climate control systems.

Maintain plant balance

How to environmental factors such as light, temperature, CO2 concentration and water supply in balance, so that the plant has the best conditions for growth.

The successful implementation of NGG concerns keeping the correct ‘plant balance’ between generative and vegetative growth. Most growers rely only on an external solarimeter to measure light intensity, the driving force behind photosynthesis.

In practice, however, it may be better to think about keeping environmental factors such as light, temperature, CO2 concentration and water supply in balance, so that the plant has the best conditions for growth. In particular, it is important to ensure a balance between the average day temperature and the daily light integral (J/cm2 or moles/m2). It is the light integral that drives the production of assimilates (the products of photosynthesis).

If light intensity is to be measured, there is a strong case for combining the standard light measurement with an internally mounted PAR (Photosynthetically Active Radiation) sensor, since this gives a better indication of the part of the overall spectrum which drives photosynthesis.

On dull days, the production of assimilates will be reduced, so if the plant is to maintain a good balance, the average temperature over 24 hours should also be correspondingly lower.

The reverse is true in high light conditions, when higher 24-hour average temperatures will maintain plant balance.

By maintaining the correct plant balance, thereby ensuring that photosynthesis and thus the production of assimilates is optimised, overall production will be higher, the crop will be less susceptible to disease, and flavour will be enhanced. Of course, growers have always tried to keep a good plant balance by adjusting temperatures according to how the plant is growing.

The key difference now is that NGG encourages growers to use the available environmental control technologies, such as weather forecasting and Temperature Integration (TI), to anticipate changes in environmental conditions, so that the climate adjustments can be made before any negative signs are seen in the crop.