First published August 2010

Learn how using an alternative position to the conventional top of the crop placement can help improve greenhouse conditions and energy efficiency.

Quick links:

- Can measuring the bottom of the crop give better results?

- Conventional vs alternative positioning

- What do the temperature measurements tell us?

- What do the humidity measurements tell us?

- What are the options?

Can measuring the bottom of the crop give better results?

Common practice is to put measuring boxes in a position that is both practically convenient and provides representative measurements of the conditions in the greenhouse.

For edible crop growers this is normally at the top of the crop whereas for ornamentals growers it is just above the crop canopy.

Now that we are trying to save energy and be more precise with our environmental controls is this good enough; or can using an alternative position give better results?

Conventional vs alternative positioning

We explore two different scenarios – positioning one measuring box at the top of the crop and one at the bottom of the crop.

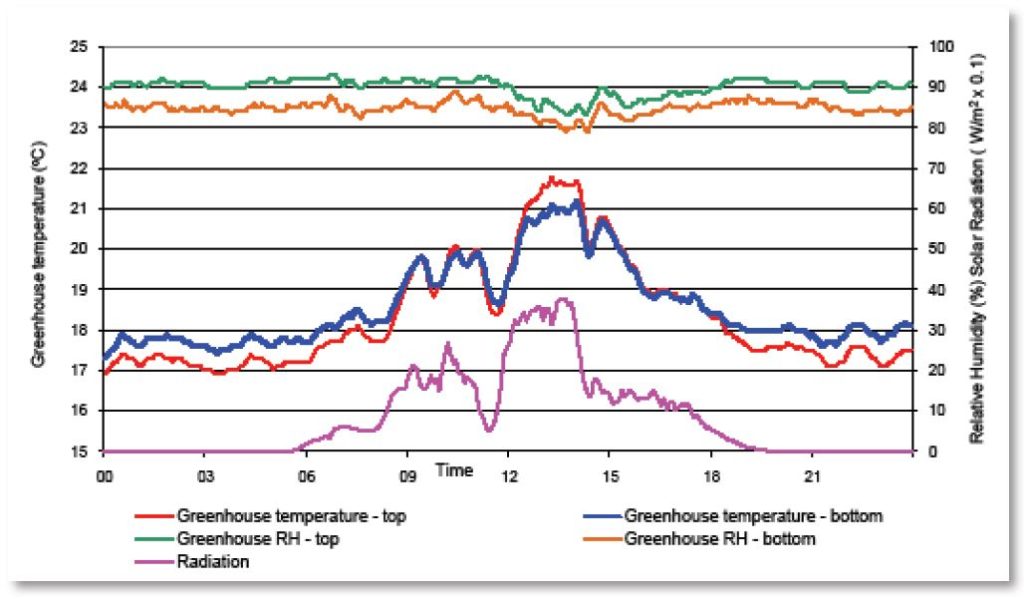

The graph in Figure 1 shows the greenhouse environment measured at Red Roofs Nursery over the course of one day.

Two measuring boxes were used positioned at:

- The conventional position at the top of the crop

- The bottom of the crop close to the stem bundles

What do the temperature measurements tell us?

During the night the energy input to the greenhouse is dominated by pipe heat, and under these conditions the temperature at the bottom of the crop is higher than at the top. On the other hand, during the day when there is significant solar radiation, the temperature is higher at the top of the crop.

This tells us that using the conventional measuring box position is fine if you are only interested in the conditions at the head of the crop. For example, if crop growth is your only concern then this location is OK.

However, if you are interested in what might be happening at the crop base, conventional practice is not going to give you accurate information. So, if you want to know about disease risk and the chance of condensation, you need to move your measuring box or use extra sensors to achieve accurate control.

What do the humidity measurements tell us?

When we look at the relative humidity measurements we can see that, on the day in question, the humidity was always higher at the top of the crop.

Again this begs the question about whether the measuring box position traditionally used by growers is correct; especially when humidity control is being carried out primarily for disease control purposes. Under these circumstances, controlling to the measurements taken from the conventional position could waste energy.

What are the options?

By simply installing an additional measuring box we have shown that relying on information from sensors placed in the traditional location alone could be both misleading and waste energy.

So is the answer to install extra measuring boxes or are there other solutions?

This is explored further in How plant temperature data helps to save energy .

For now one thing is clear, current commercial practice is a compromise and that by taking greater care with the measurements we take we can make energy savings.